- By 小编

- 2025-07-24 14:04:46

- Industry Information

Breaking the AGV Bottleneck: A Leap from Automation to Resilient Intelligence in the Supply Chain

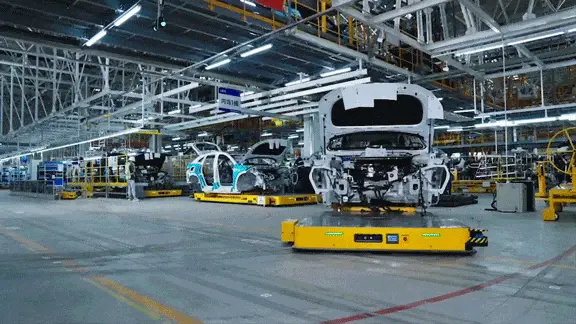

In today’s global logistics landscape, traditional AGV (Automated Guided Vehicle) applications are reaching their upper limit. Once centered on automating repetitive tasks in predictable environments, AGVs now face an urgent need to evolve in response to increasingly complex supply chain challenges. These include cross-border disruptions, labor shortages, customization demands, and multi-site coordination. The shift is clear: the market is transitioning from basic automation to intelligent, flexible, and resilient systems.

.jpg)

From Mechanical Efficiency to Intelligent Autonomy

First-generation AGVs focused on task replacement, relying on fixed routes, single-mode navigation, and manual scheduling. But as production lines become more agile and unpredictable, such rigid AGV systems can easily become bottlenecks. To cope with dynamic demands, next-generation AGVs are evolving into autonomous mobile robots (AMRs) equipped with high-precision sensors, multi-mode navigation, AI-based decision-making, and self-learning algorithms. These intelligent systems can autonomously adjust paths, respond to disruptions, and optimize workflows on the fly.

Building Supply Chain Resilience with Smart AGVs

AGVs are no longer isolated tools but integrated nodes within an interconnected supply chain. Through IoT connectivity, cloud platforms, and real-time data exchange, modern AGVs can communicate with warehouse systems, MES, and even ERP platforms. This enables real-time material tracking, delay forecasting, and intelligent dispatching. In turn, this level of connectivity significantly improves visibility and responsiveness across the supply chain, helping companies mitigate uncertainty and risk.

Flexibility and Scalability: Core Attributes of the Future AGV

In an environment of fluctuating order volumes and diversified scenarios, modular AGV platforms provide key advantages. These include compatibility with different payloads, quick adaptation to various navigation environments (indoor, outdoor, mixed terrain), and remote configuration updates. Moreover, the integration of 5G and edge computing allows for low-latency decision-making and fleet collaboration, which is critical for large-scale deployment.

Toward the Smart and Resilient Factory of the Future

As manufacturers accelerate digital transformation, the role of AGVs is expanding beyond simple logistics. Intelligent AGVs are now integrated into lean production lines, participating in just-in-time material delivery, quality traceability, and even emergency response logistics. In smart factories, AGVs serve not only as transport tools but also as mobile sensors and data hubs, feeding critical data back into digital twin systems and production planning platforms.

Conclusion

The AGV industry is undergoing a paradigm shift—from standalone automation devices to dynamic, intelligent, and resilient systems. This evolution is redefining how enterprises manage supply chains in a volatile world. Manufacturers and solution providers must jointly innovate, combining AI, data, and hardware design to usher in a new era of flexible, intelligent intralogistics.