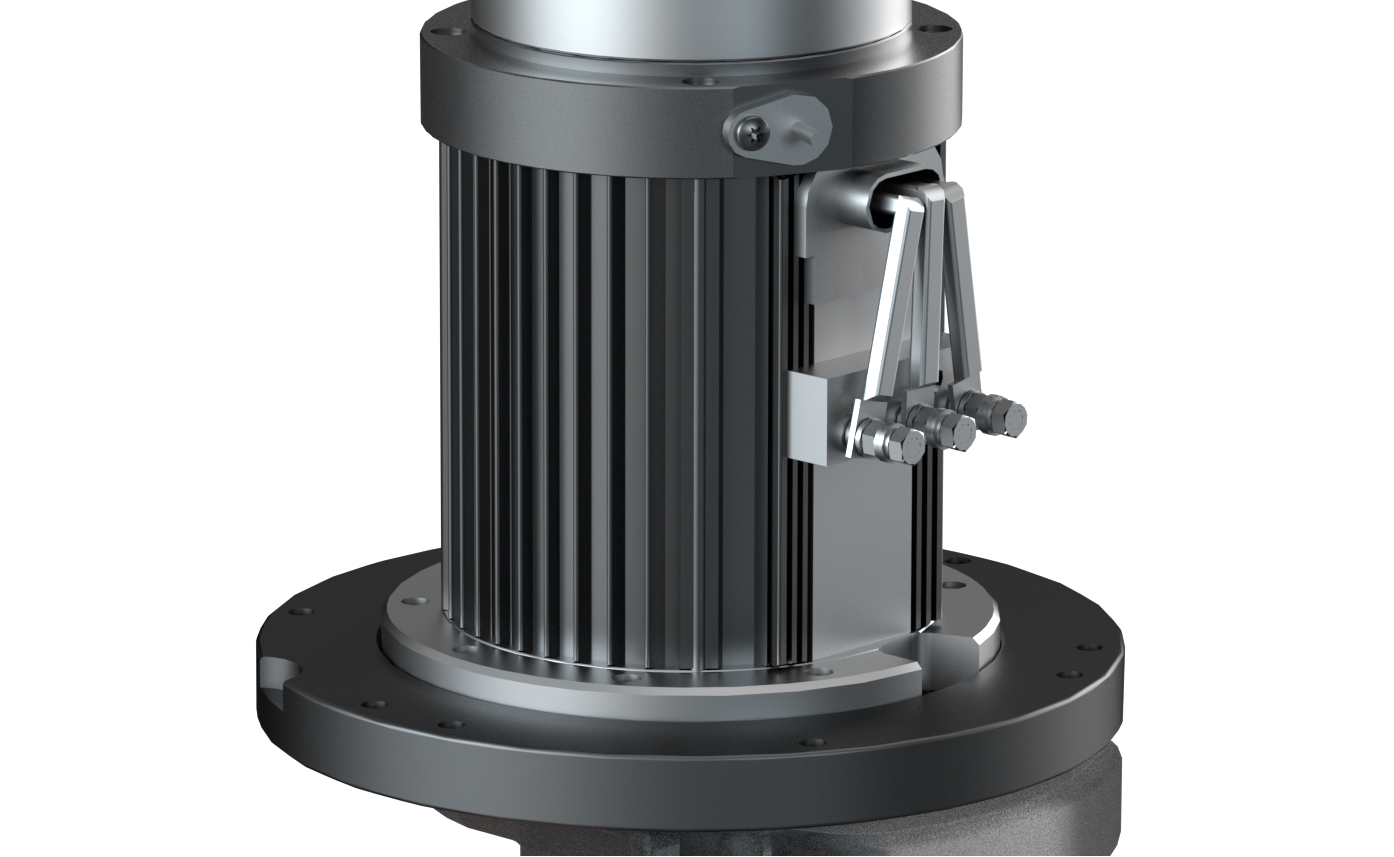

Product Introduction

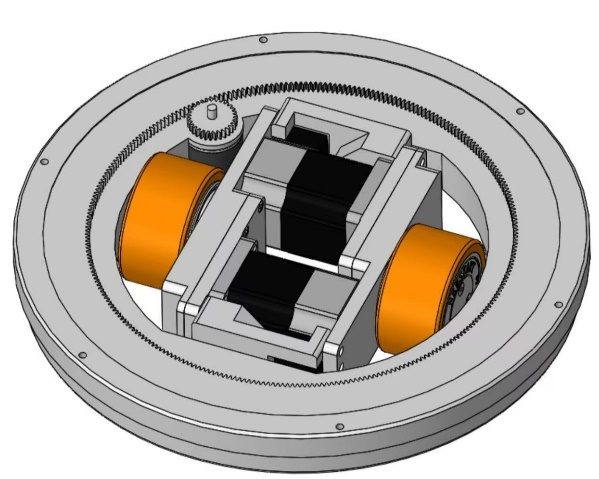

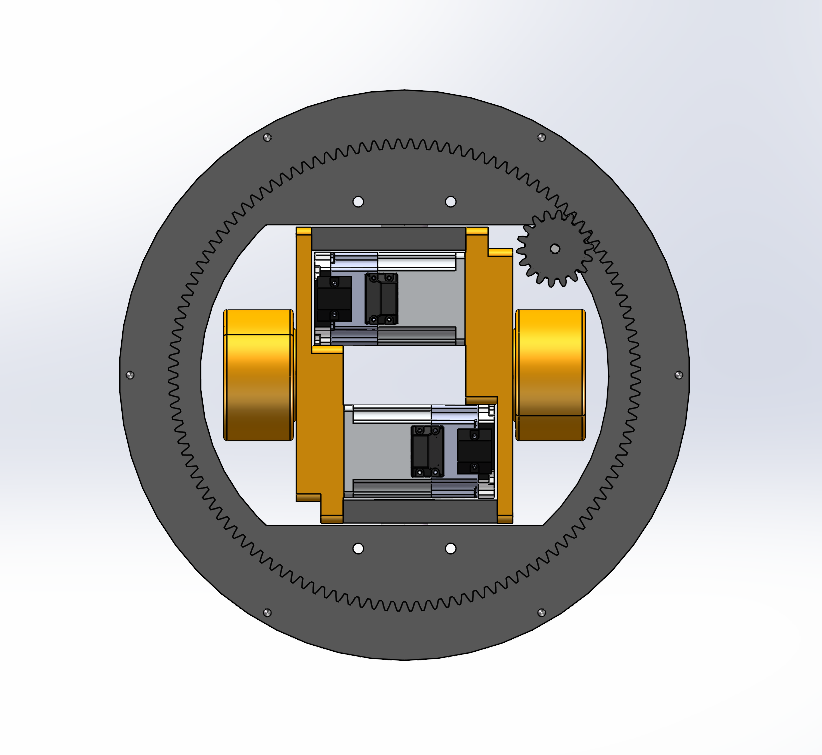

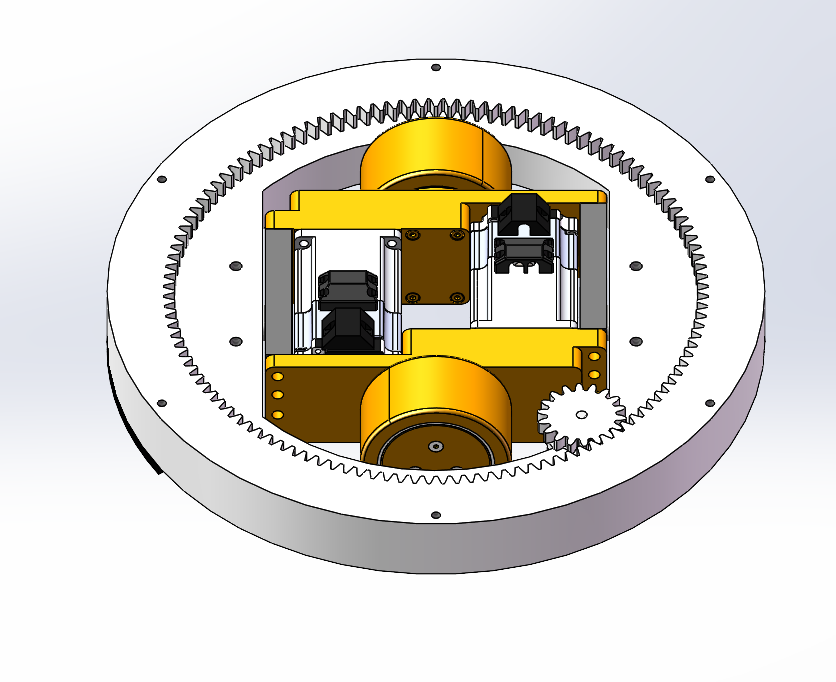

TEC series vertical drive wheel with steering is a high-performance drive solution designed for AGV (automatic guided vehicle) and industrial robots. Its compact structure and extremely small turning radius design ensure flexible movement in space-constrained scenarios. It uses high-quality materials and advanced manufacturing processes.

1. Bevel gear transmission structure, compact structure, low noise, and high output torque;

2. Vertical drive wheel series (named by wheel diameter mm): 150, 230, 250, 310, 343, 406, 457, 470 series application coverage.

3. Load range: 500kg-6500kg series;

4. 12V-96V input voltage range, vertical with steering/without steering;

5. Optional polyurethane wheel or rubber wheel structure;

6. Optional DC brush, AC asynchronous, permanent magnet servo motor, power range 400W-16KW;

7. Optional parts: shock-absorbing spring, limit switch, original switch, incremental/absolute encoder, potentiometer and other components.

8. Custom series: explosion-proof drive wheel, low temperature drive wheel, high IP protection level.

With excellent performance and multi-scenario adaptability, TEC series vertical drive wheel with steering is widely used in various automation equipment, helping enterprises to achieve efficient logistics and precise navigation.

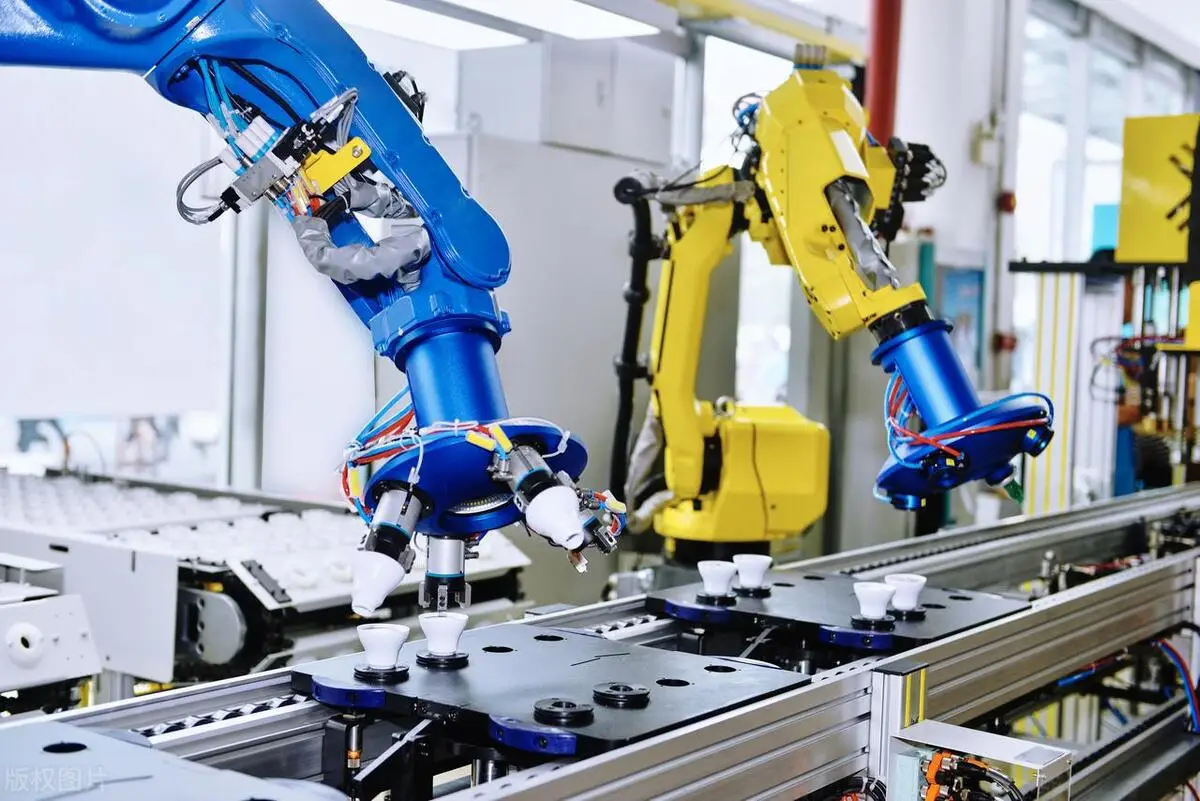

Application Scenario

· Forklift: The compact design of the vertical drive wheel makes the forklift more compact, flexible and easier to operate.

Automated Guided Vehicles (AGVs): Ideal for automating material handling within factories. Their compact design and high maneuverability allow them to navigate narrow aisles with ease, while their powerful motors ensure they can handle a wide range of loads.

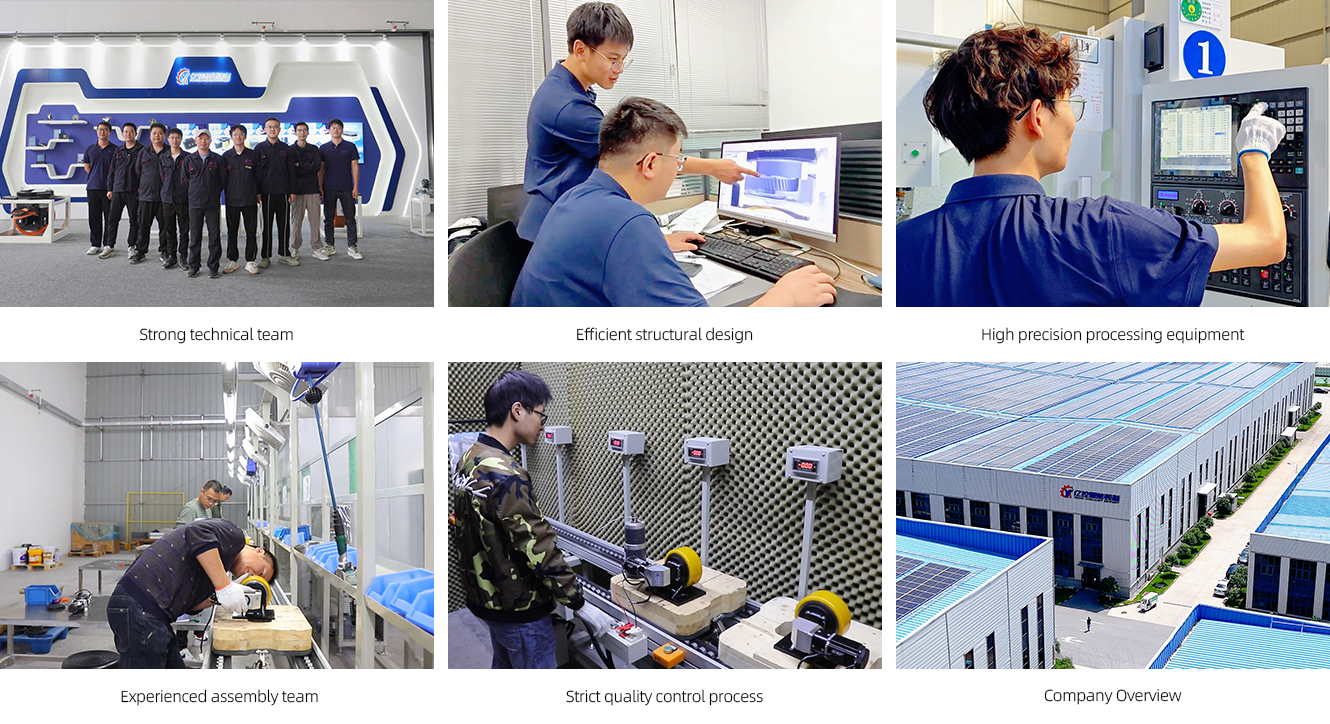

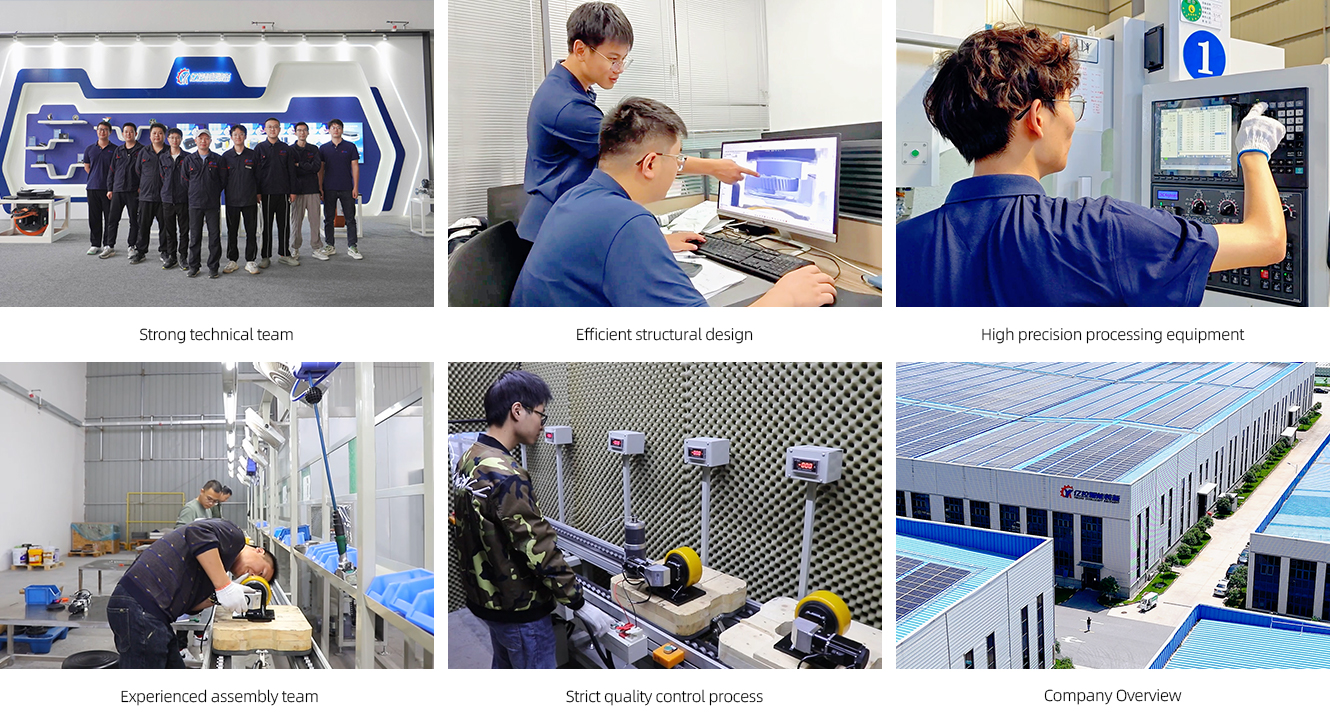

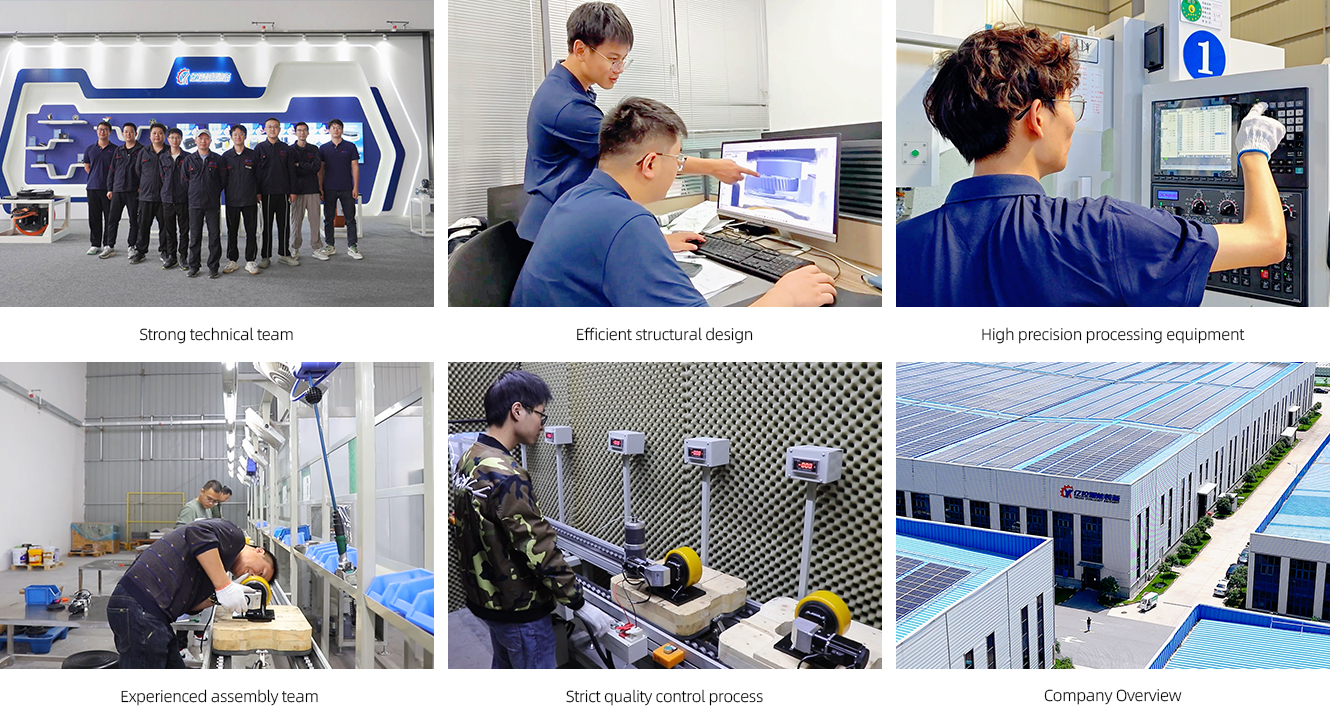

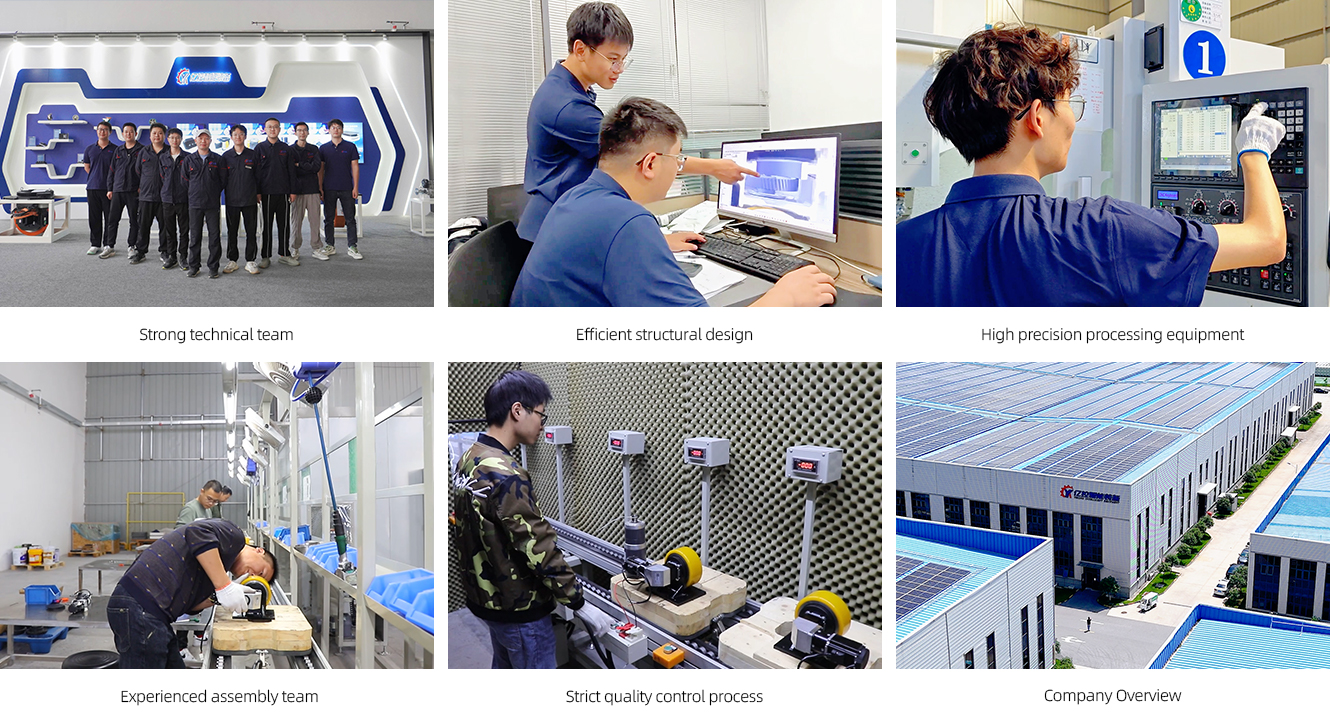

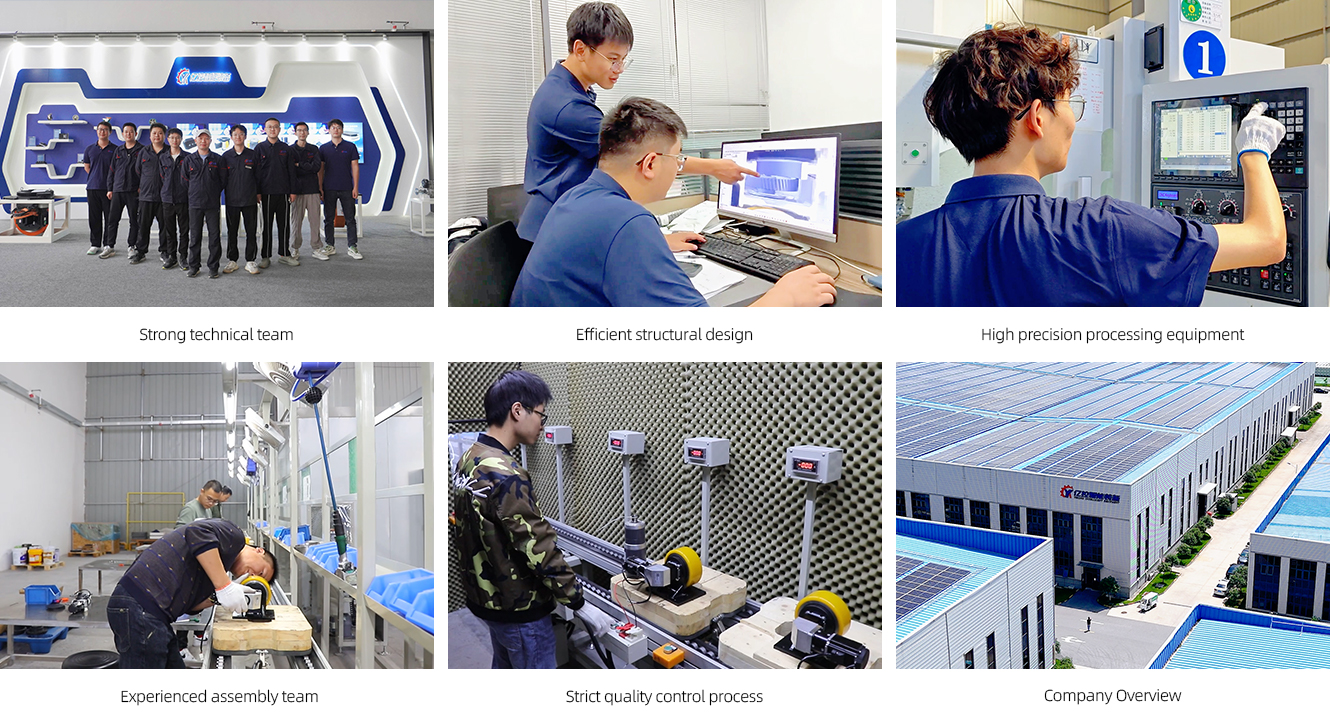

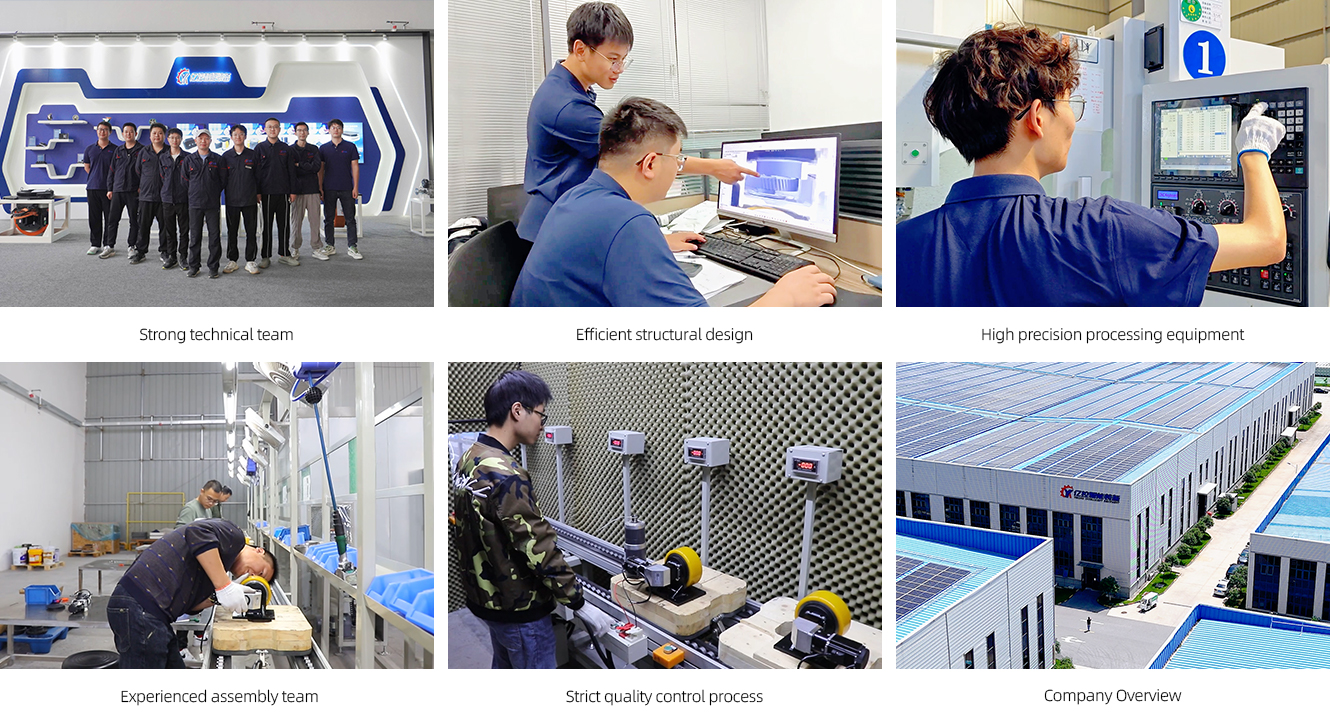

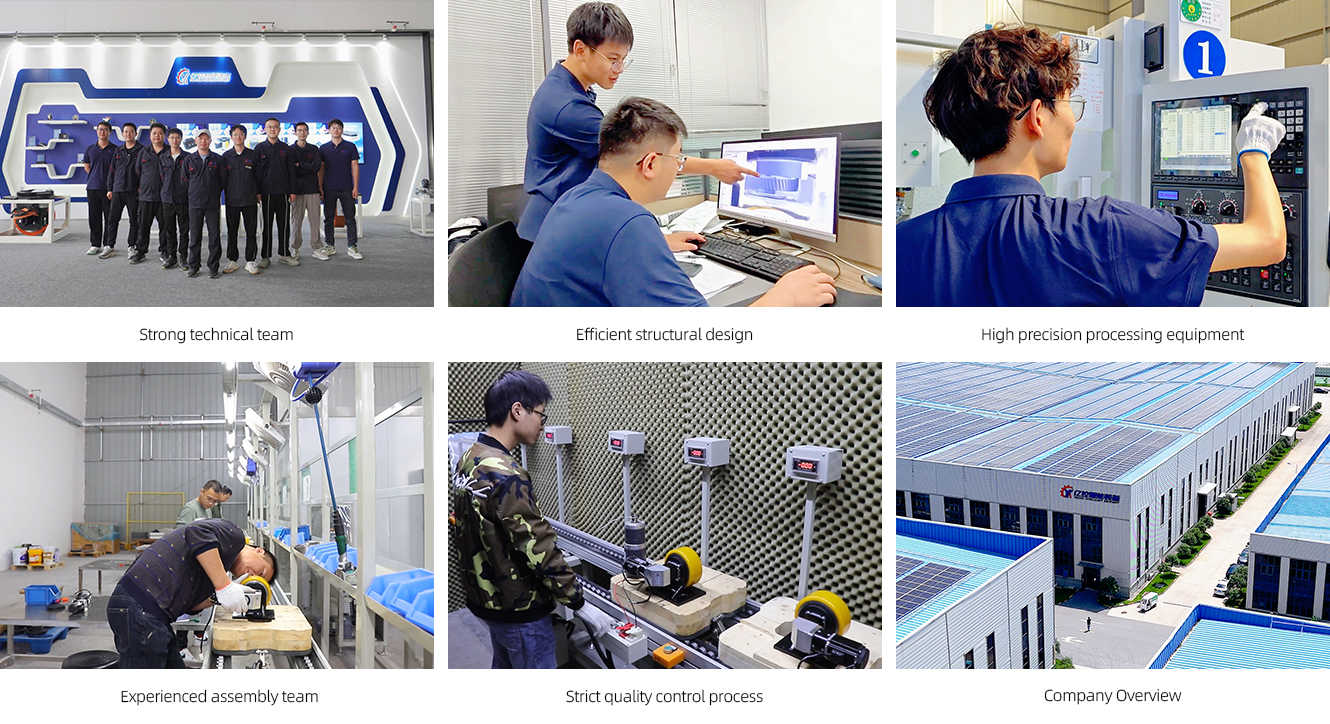

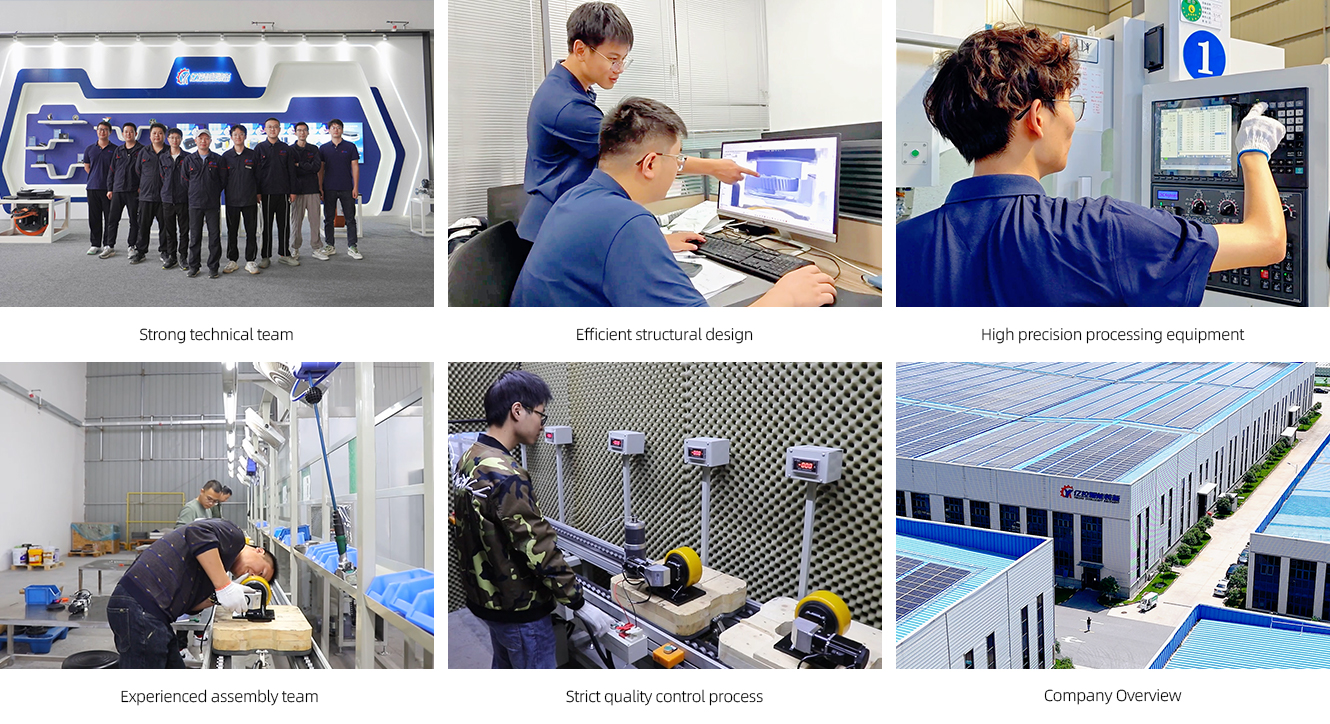

Six quality assurances