Product Introduction

A motor reducer, also known as a gearbox, is a mechanical transmission device that connects a motor to a driven load. It consists of a series of gears that are used to change the torque and speed between the motor and the load. Understanding torque and speed is critical. The reducer increases the motor torque and allows the receiving component to rotate. Manufacturers specify the minimum and maximum torque (in N.m) that their products can support. Planetary gearboxes have high torque density. Motor reducers can also reduce motor speed. Consider the ideal reduction ratio for your application. Based on the motor speed, the reduction ratio determines the output speed (in revolutions per minute). Finally, determine the most appropriate gear reducer assembly (coaxial, parallel shaft, or orthogonal input/output shafts) for your application.

Application Scenario

Warehousing and Logistics:

Stackers, conveyors and other equipment in automated warehousing systems also require motor reducers to achieve efficient cargo handling and storage.

Automated production line:

In various automated production lines, motor reducers are used to drive conveyor belts, elevators, sorting equipment, etc. For example, in food processing production lines, reducers ensure that the conveyor belts run at a stable speed and accurately transport food for processing and packaging.

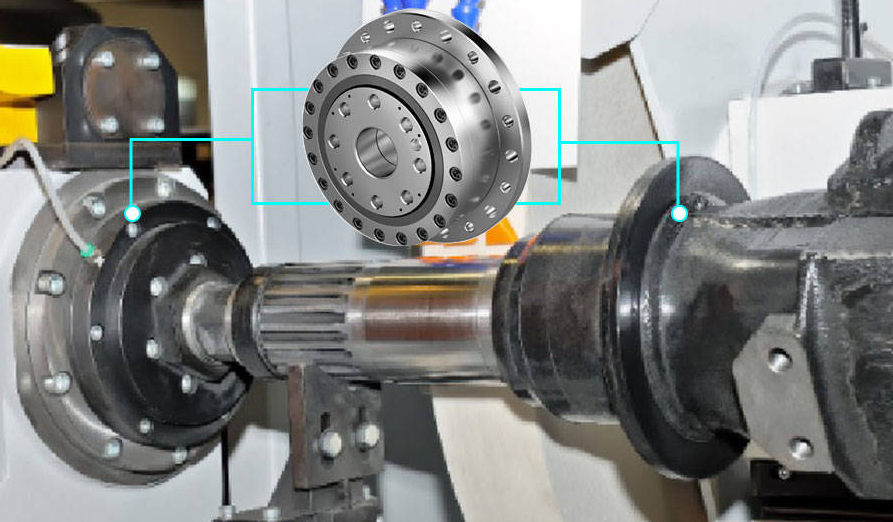

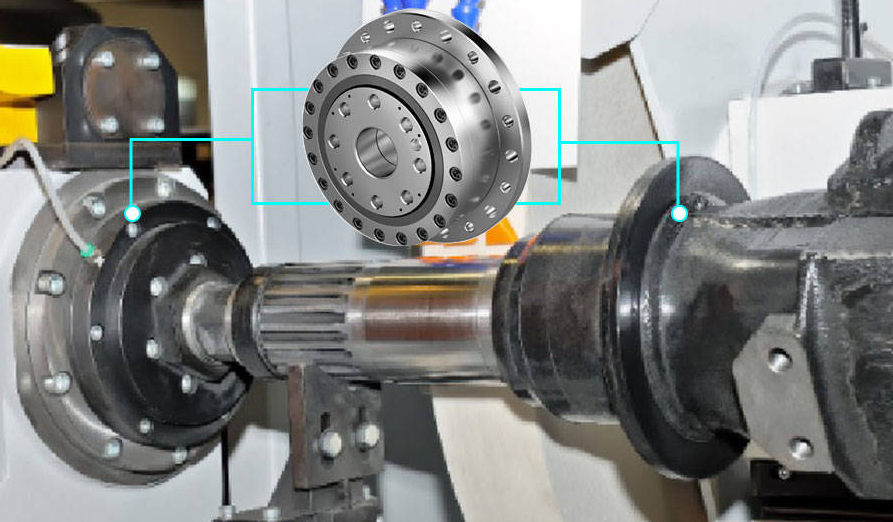

Machine tool equipment:

The spindle drive and feed systems of CNC machine tools, milling machines, drilling machines and other machine tools usually require motor reducers to achieve precise speed control and high torque output, ensuring that the machine tools have stable cutting force and processing accuracy when processing different materials and workpieces.

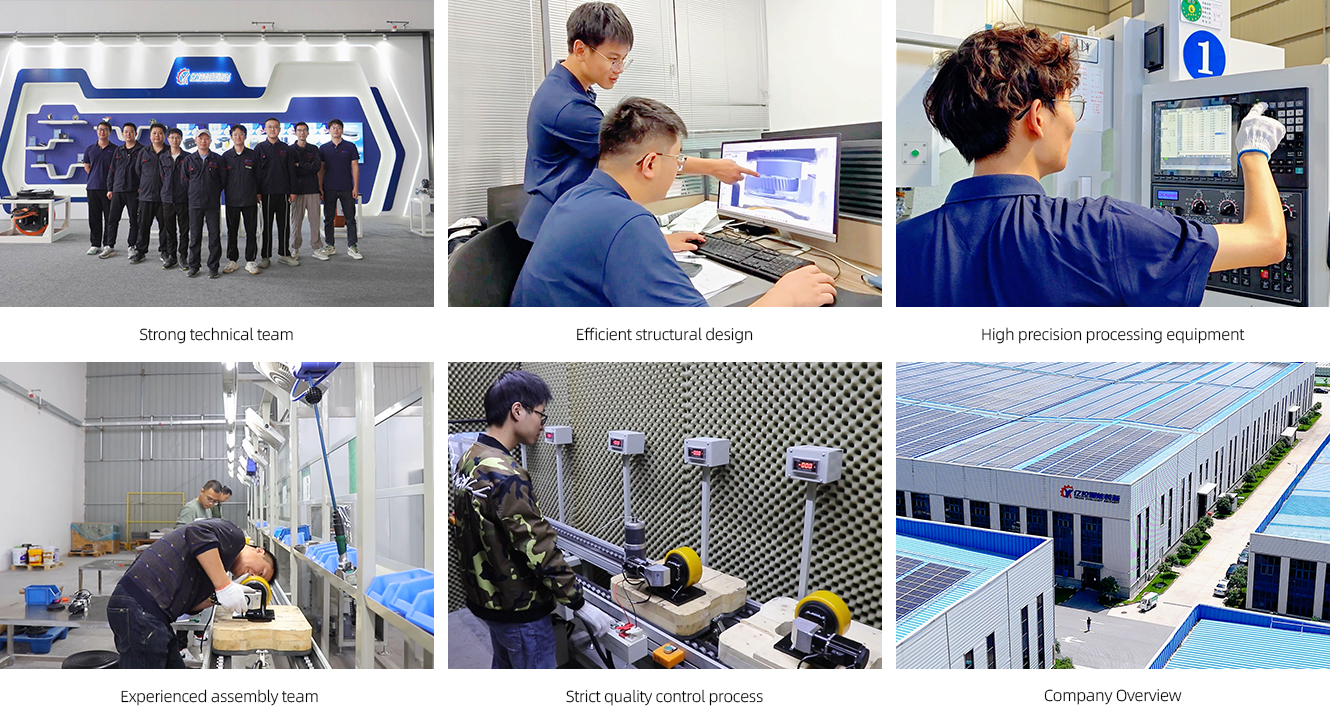

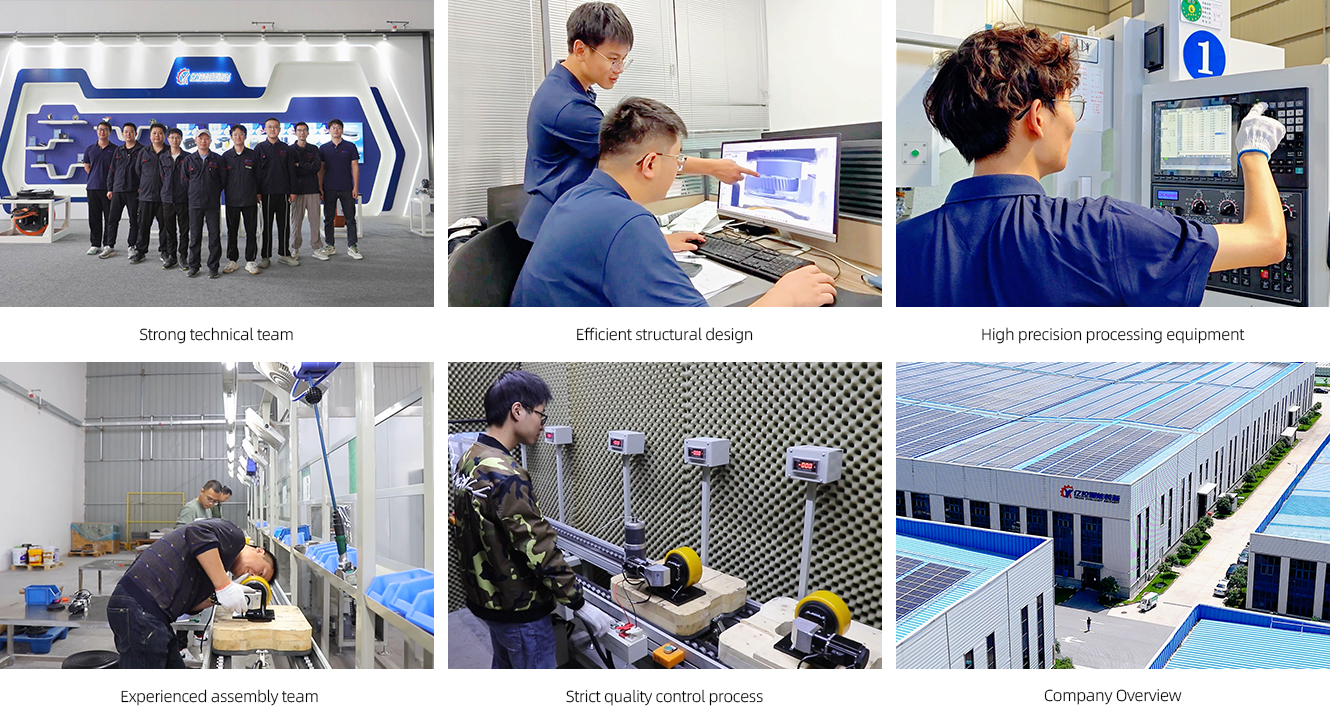

Six quality assurances

Product parameters (specifications)

Specification | Number of stages | Reduction ratio | AB042 | AB060 | AB000 | AB115 | AB142 | AB180 | AB220 |

Nominal output torque | 1 | 3 |

| 55 | 135 | 220 | 450 | 1186 | 2308 |

| 4 | 23 | 65 | 165 | 345 | 700 | 1548 | 2167 |

|

| 5 | 21 | 60 | 160 | 335 | 650 | 1431 | 2347 |

|

| 6 | 20 | 52 | 145 | 300 | 610 | 1376 | 206 |

|

| 7 |

| 50 | 135 | 290 | 540 | 1151 | 1771 |

|

| 8 | 18 | 45 | 115 | 265 | 510 | 1000 | 1600 |

|

| 9 | 14 | 42 | 105 | 255 | 455 | 910 | 1500 |

|

| 2 | 10 | 14 | 42 | 105 | 255 | 455 | 910 | 1500 |

| 12 | 23 | 65 | 165 | 345 | 700 | 158 | 2563 |

|

| 15 | 21 | 60 | 160 | 335 | 650 | 1431 | 2347 |

|

| 25 | 21 | 60 | 165/160 | 345/335 | 700/650 | 1568/1431 | 2567/2347 |

|

| 28 | 23 | 65 | 165 | 345 | 700 | 1508 | 2567 |

|

| 30 |

|

| 335 |

|

| 2347 |

|

|

|

| 21 | 60 | 160 | 650 | 1431 |

|

|

|

| 35/40 | 21 | 60 | 160/160 | 335/335 | 650/650 | 1431/1431 | 2347/2347 |

|

| 45/50 | 21 | 60 | 160/160 | 335/335 | 650/650 | 1431/1431 | 2347/2347 |

|

| 60 | 20 | 52 | 145 | 300 | 610 | 1376 | 2068 |

|

| 70/80 | 18 | 50/45 | 135/115 | 290/265 | 540/510 | 1151/1000 | 1771/1600 |

|

| 90 | 14 | 42 | 105 | 255 | 455 | 910 | 1500 |

|

| ≥3 | ≥100 | For detailed parameters of gear reducers with three or more reduction stages, please consult the factory service. The specific parameters shall be subject to the appearance drawing. |

|

|

|

|

|

|

Maximum acceleration torque T2 | Nm | 142 | 1.8*T (1.8 times rated torque) |

|

|

|

|

|

|

Emergency stop torque T2 | Nm | 142 | 3*(3 times rated torque) |

|

|

|

|

|

|

Rated input speed | r | 142 | 3000 | 3000 | 3000 | 3000 | 2000 | 1500 | 1000 |

Maximum input speed | T | 142 | 6000 | 6000 | 6000 | 6000 | 4000 | 3000 | 2000 |

Precision clearance |

|

|

| 3 | 3 | 3 | 3 | 5 | S |

P1 | 1 | 3 |

|

|

|

|

|

|

|

-Arc Minutes | 2 | 5 | 5 | 5 | 5 | 5 | 7 | 7 |

|

P2 -Arc Minutes | 1 | S | 5 | 5 | 5 | 5 | 7 | 7 |

|

| 2 | 7 | 7 | 7 | 7 | 9 | 9 |

|

|

noise | d(A) | 142 | 58 | 60 | 60 | 63 | 65 | 67 | 70 |

Maximum radial load capacity | N | 142 | 770 | 1500 | 3200 | 6700 | 9600 | 14000 | 16000 |

Maximum axial load capacity | N | 142 | 380 | 760 | 1600 | 3300 | 4800 | 7000 | 8000 |

efficiency | % | 1 | ≥97% |

|

|

|

|

|

|

| 2 | >9 |

|

|

|

|

|

|

|

Operating temperature | ℃ | 142 | -15 - +40°C |

|

|

|

|

|

|

Service life | h | 142 | ≥20000 |

|

|

|

|

|

|

lubricating |

| 142 | Synthetic grease (lifetime maintenance-free) |

|

|

|

|

|

|

FAQ

Using a reducer or gearbox to reduce the motor speed and increase the output torque is equivalent to improving the working capacity of the motor. In addition, the output direction can also be changed through the reducer.

Use a gearbox or gear set to reduce the speed of the motor. This involves connecting the motor shaft to a gear system where the output shaft rotates at a slower speed than the motor.

A gear reducer is a device used to transfer mechanical power from an electric motor or other drive to the driven load. In the pump world, they convert high-speed pumps to lower-speed pumps.