Product Introduction

Polyurethane is superior to rubber in resisting grease, oil, cuts, chips and abrasion. These castors can be used in almost any factory floor. As with Moldon rubber, the adhesive that secures the polyurethane tire (tread) to the core can be affected by certain chemicals, shock, overloading and heat build-up. Under manual operation under ideal conditions, the safe operating capacity of a polyurethane castor is three times the capacity of a rubber wheel of the same size. Capacity ratings are the capacity that the wheel can carry without failure. They are not absolute but depend on usage and service.

Application Scenario

Logistics handling equipment:

In factories, warehouses and other places, polyurethane wheels are widely used in various logistics handling equipment, such as trolleys, forklifts, stackers, etc. Polyurethane wheels can withstand a large weight of goods, maintain stable operation under different ground conditions, reduce vibration and noise of equipment, and improve work efficiency.

Automated production line:

In automated production lines, polyurethane wheels can be used as wheels for conveying equipment, such as conveyor belts, rollers, etc. The high precision and low friction coefficient of polyurethane wheels can ensure the stability and accuracy of products during transportation and reduce product damage and waste.

Processing equipment:

Some machining equipment, such as machine tools and milling machines, also use polyurethane wheels as wheels of moving parts. The wear resistance and impact resistance of polyurethane wheels can ensure the stability of the performance of the equipment during long-term use and reduce the maintenance and replacement costs of the equipment.

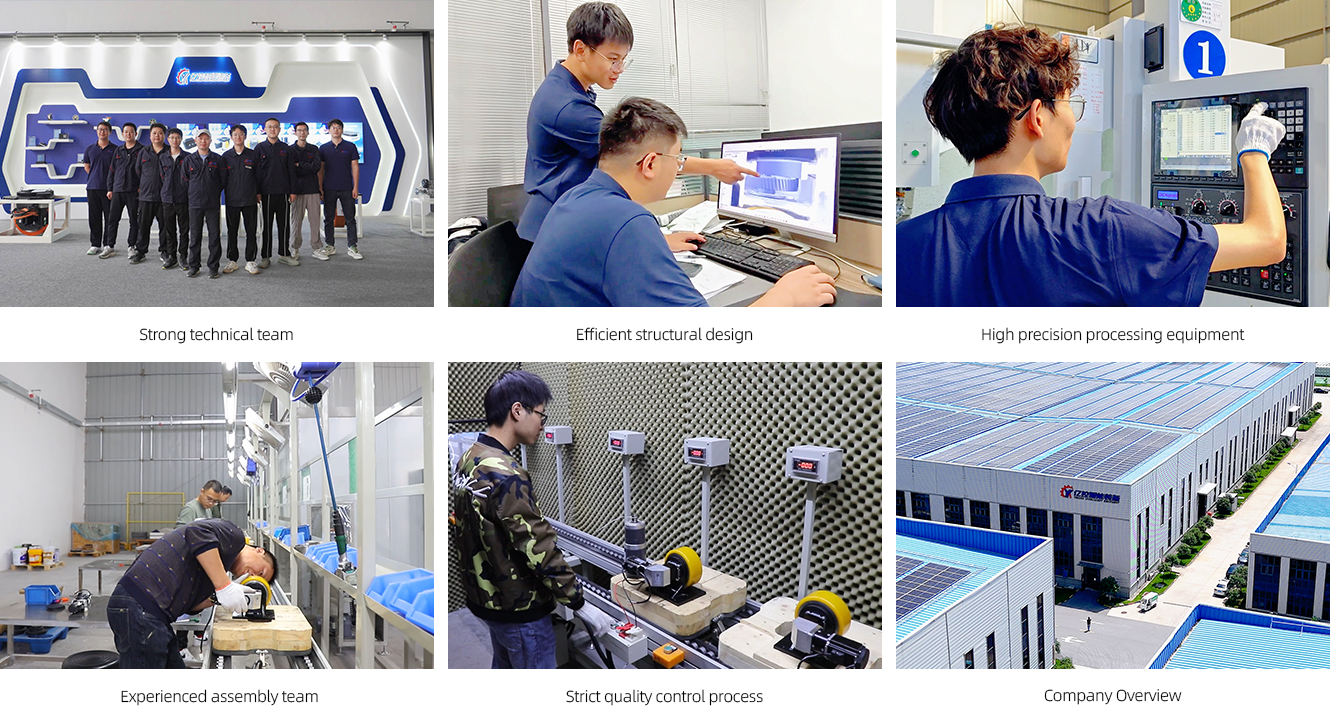

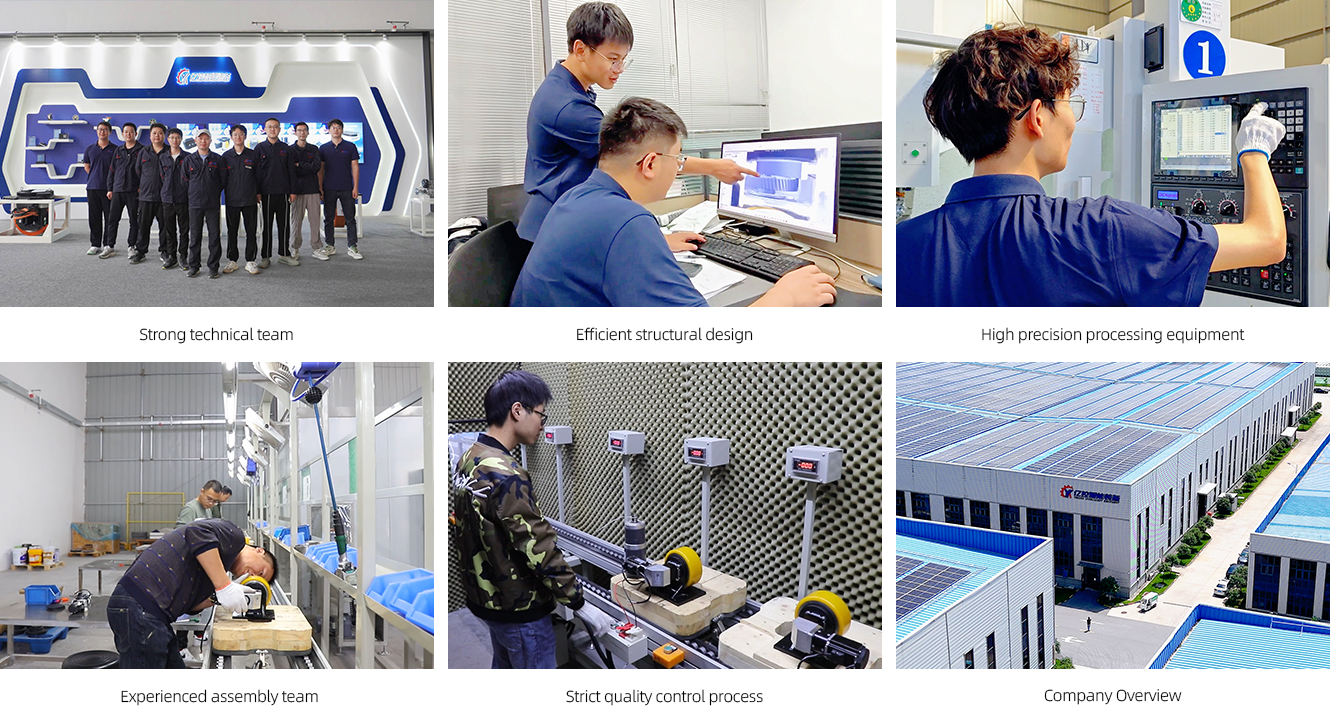

Six quality assurances

Product parameters (specifications)

Ultimate tensile strengthDynamic load capacityAbrasion and tensile resistanceObstacle-crossing ability

| TR Polyurethane Material | TR-ROLL polyurethane material | VULKOLLAN |

hardness | 92 +/- 3 Shore A | 75 - 80 Shore A | 92 +/- 3 Shore A |

Elasticity | 44 +/- 6% | 72 +/- %4 | 60 +/- 5% |

Wear | 40 +/- 5 mms | 45 +/- 7 mm | 40 +/- 5 mm3 |

35 +/- 7 MPa | 30 +/- 5 MPa | 45 +/- 7 MPa |

|

Extreme stretch | 300 +/- 50% | 440 +/- 40% | 550 +/- 50% |

Tensile strength | 120 + / + 30 kN/m | 90 +/- kN/m | 160 +/- 20 kN/m |

Excellent | Excellent | Excellent |

|

Rolling resistance | good | Excellent | Good |

Resistance to high speed operation | good | Excellent | Excellent |

Excellent | Excellent | Excellent |

|

Comfort | good | Excellent | good |

Excellent | Excellent | good |

|

Excellent | good | good | Excellent |

Oil resistance | good | good | good |

Hydrolysis resistance | medium | medium | medium |

High temperature resistance | Up to 80 °C | Up to 70 °C | Up to 80 °C |

Low temperature resistance | Up to -20 °C | Up to -20 °C | Up to -20 °C |

FAQ

To extend the service life of polyurethane wheels, proper maintenance is required. Clean the wheels regularly to avoid dust and debris accumulating on the surface and inside of the wheels. Check the wear of the wheels and replace the wheels that are severely worn in time. During use, avoid overloading and high-speed driving to reduce wheel wear and damage.

The installation of polyurethane wheels is relatively simple. Generally, the wheels are installed on the equipment through bolts, nuts and other connectors. During the installation process, it is necessary to ensure that the wheels are installed firmly to ensure the safe operation of the equipment.

Polyurethane wheels have a certain tolerance to general chemicals, but they may be damaged by highly corrosive chemicals such as strong acids and alkalis. If you must contact chemicals during use, it is recommended to first understand the tolerance of polyurethane wheels to chemicals.

Polyurethane wheels can be used outdoors, but the impact of environmental factors on the wheels needs to be considered. For example, in harsh environments such as high temperature, low temperature, and humidity, the performance of polyurethane wheels may change. At the same time, when using them outdoors, you must also pay attention to avoid sharp objects scratching and damaging the wheels.

Polyurethane wheels can be used on various floors, including cement floors, tile floors, wooden floors, carpets, etc. They have good grip and stability and can adapt to the friction coefficient and hardness of different floors.

The noise generated by polyurethane wheels during operation is relatively small. Its special material and structural design make the wheels run more smoothly and quietly, which is particularly suitable for places with strict noise requirements such as hospitals, libraries, and shopping malls.

Polyurethane wheels usually have a higher load-bearing capacity. Polyurethane wheels of different specifications can be selected according to different needs to meet different load-bearing requirements. Generally speaking, industrial-grade polyurethane wheels can carry heavier goods and equipment.

Polyurethane wheels have excellent wear resistance. Compared with traditional rubber wheels, polyurethane wheels can be used for a long time under various complex ground conditions without being easily worn, which greatly extends the service life of the wheels.