Product Introduction

Four-point contact ball slewing bearings are mainly composed of inner and outer rings, single-row steel balls, cages (or partitions), sealing devices, etc. The inner and outer rings can be integral structures or split structures. The integral ring has greater rigidity, and the split structure is more convenient to adjust. The two split rings are bolted together when leaving the factory.

Four-point contact ball slewing bearings generally have cages (or partitions), and the full ball structure is only used for heavy-load conditions, because the full ball structure has strong bearing capacity, but the friction is also large, which is easy to scratch the surface of the steel ball.

The basic structures of four-point contact ball slewing bearings/slewing bearings are toothless, external gear, and internal gear, all of which have high static load capacity.

Application Scenario

Forklift AGV:

The operating environment faced by forklift AGV is relatively complex, so the AGV (automatic guided vehicle) slewing bearing used for the drive wheel also needs stronger stability, and the surface also needs to be specially treated to cope with the special environment.

CT:

During the operation of the CT machine, the X-ray tube and detector rotate around the patient at the same time, generating tomographic images, through which doctors obtain important information required for diagnosis.

During the high-speed rotation of the CT machine, in order to ensure a quiet medical environment, low-noise, high-operation-precision medical equipment slewing bearings (turntable bearings) are extremely important.

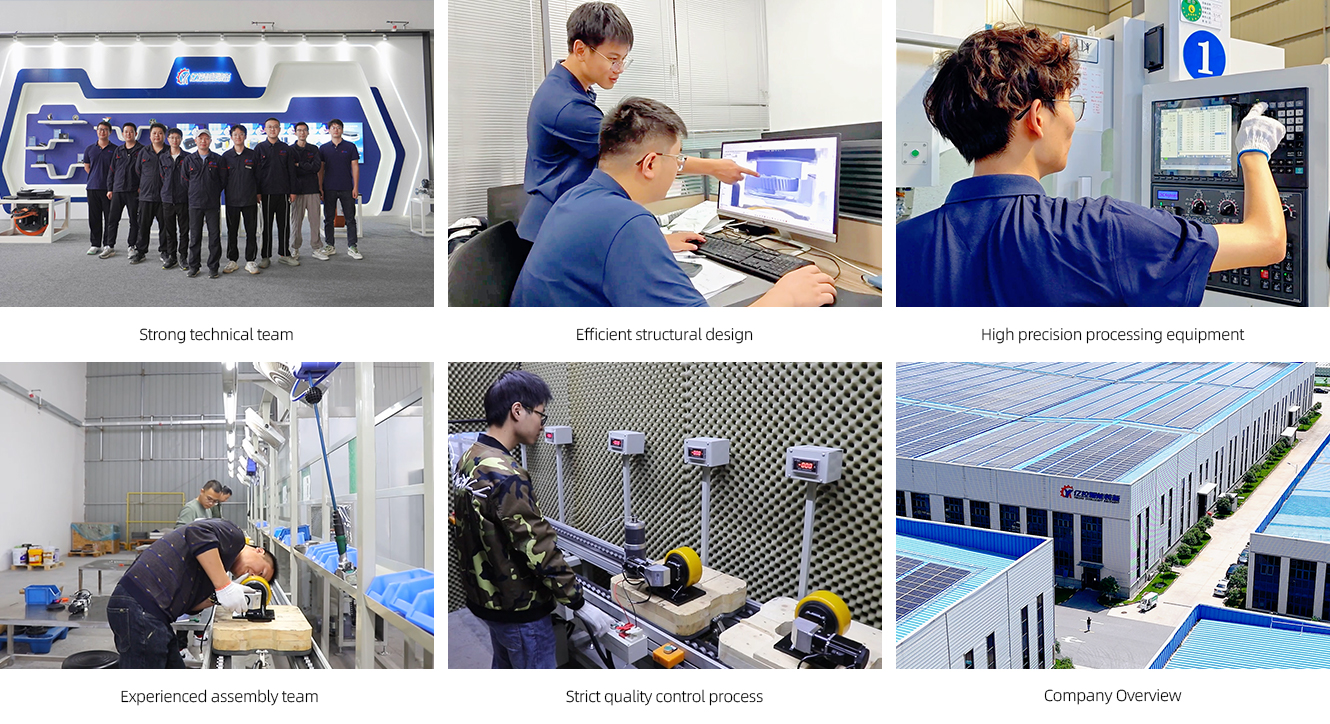

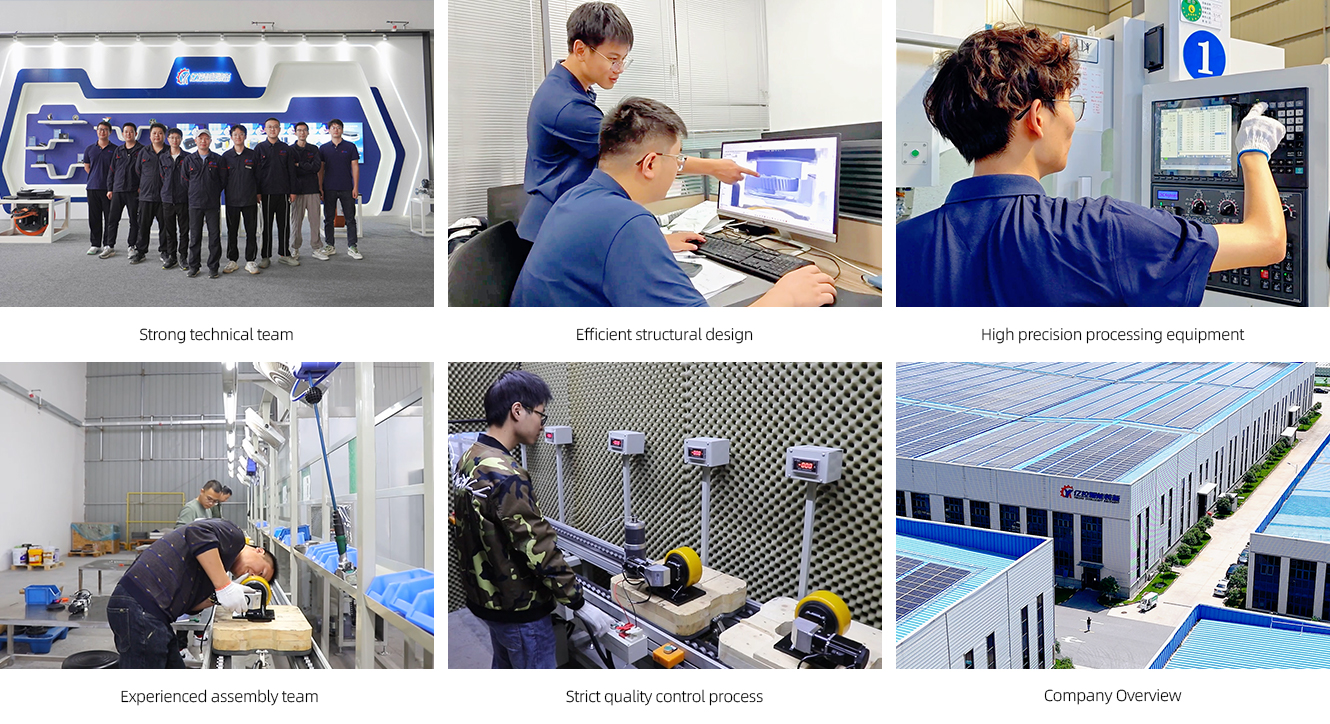

Six quality assurances

Product parameters (specifications)

Gear basic parameters table

model | Tooth profile type | Modulus (m) | Number of teeth (Z) | Tooth angle (α) | Addendum coefficient (h) | Displacement coefficient (x) |

TEC - 150P750SP | Involute | 1.5 | 110 | 20° | 1.0 | 0 |

TEC - 167P400SP | Involute | No value specified | 114 | 20° | 1.0 | 0 |

TEC - 167(V2.1) | Involute | 3 | 40 | 20° | 1.0 | 0 |

TEC - 300 | Involute | 2.5 | 127 | 20° | 1.0 | -0.28 |

TEC - 410 | Involute | 2.5 | 180 | 20° | 1.0 | -0.28 |

跨距及偏差相关参数表格

型号 | 跨距(Wx) | 跨测齿数 Across (K) | 上偏差 (Es) | 下偏差 (Es) |

TEC - 150P750SP | 57.66 | 13 | 无明确单位标注(按上下文应为 mm) | 无明确单位标注(按上下文应为 mm) |

TEC - 167P400SP | 7.9 | 13 | -0.198 | 无明确单位标注(按上下文应为 mm) |

TEC - 167 | 87.83 | 12 | -0.320 | 无明确单位标注(按上下文应为 mm) |

TEC - 300 | 103.6 | 14 | 无明确单位标注(按上下文应为 mm) | 无明确单位标注(按上下文应为 mm) |

TEC - 410 | 14.74 | 20 | 未明确说明上偏差对应信息(表格中名称为 Etes Wk Ebei 与其他不同) | 未明确说明下偏差对应信息(表格中名称为 Etes Wk Ebei 与其他不同) |

精度相关参数表格

型号 | 单个齿距偏差 (±f pt) | 齿距累计总偏差 (Fp) | 齿廓计值范围 | 齿廓总偏差 (Fa) | 螺旋线计值范围 | 螺旋线总偏差 (Fβ) | 径向跳动 (Fγ) |

TEC - 150P750SP | ±0.012 | 0.049 | 无明确单位标注(按上下文应为 mm) | 0.014 | 无明确单位标注(按上下文应为 mm) | 0.016 | 0.039 |

TEC - 167P400SP | ±0.024 | 0.098 | 9.30 | 0.028 | 17 | 0.032 | 0.078 |

TEC - 167 | ±0.026 | 0.036 | 14.03 | 0.100 | 13.10 | 0.032 | 0.080 |

TEC - 300 | ±0.029 | 0.131 | 11.39 | 0.041 | 19 | 0.034 | 0.105 |

TEC - 410 | ±0.029 (推测 ±f 区为 ±f pt) | 0.131 | 11.75 | 0.041 | 23.75 (推测 LA 为 Lβ) | 0.038 | 0.105 (推测 Fy 为 Fγ) |

FAQ

Many application requirements influence the selection of the appropriate slewing bearing. These considerations include speed, contamination protection, accuracy, frictional resistance, and the temperature range of the operating environment.

Slewing bearings enable and facilitate rotational motion in wind turbines, excavators, cranes and tunnel boring machines, among others.

Slewing bearings consist of an inner ring and an outer ring, one of which usually houses the gear. Both inner rings have mounting holes that enable simple and quick connection between adjacent machine parts, thus achieving optimized power transmission.