Product Introduction

The horizontal parallel axis steering wheel adopts a parallel axis structure design, which can ensure that the equipment can run smoothly and efficiently in multiple directions such as front and back, left and right. This structure gives the product excellent performance under medium load conditions and is an ideal choice for flexible operation requirements in industrial automation systems.

1. Compact structure, low noise, high output torque;

2. Horizontal drive wheel series (named by wheel diameter mm): 167, 210, 220, 250, 270, 280, 300 full range application coverage;

3. Horizontal drive wheel load range: 400kg-20000kg series;

4. 12V-96V input voltage range, horizontal with steering/without steering;

5. Optional polyurethane wheel or rubber wheel structure;

6. Optional DC brush, AC asynchronous, permanent magnet servo motor, power range 400W-15KW;

7. Optional components: shock absorbing spring, limit switch, original switch, incremental/absolute encoder, potentiometer and other components.

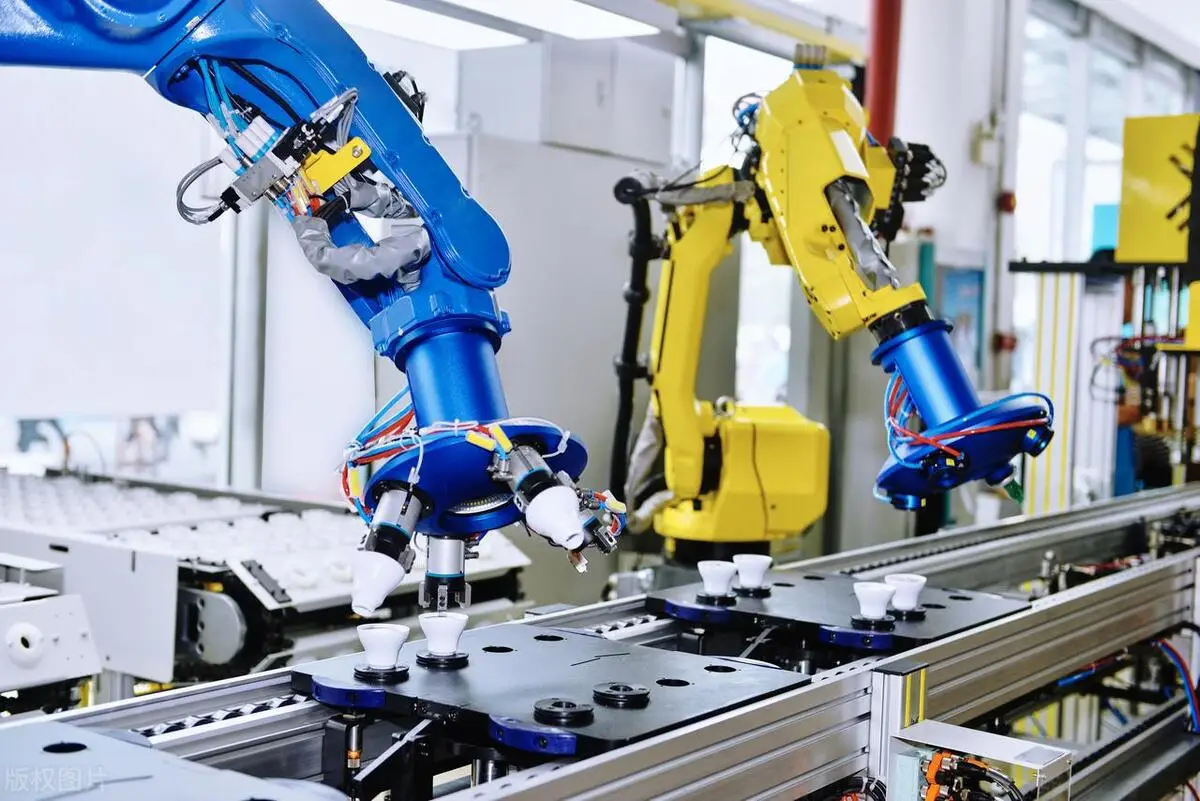

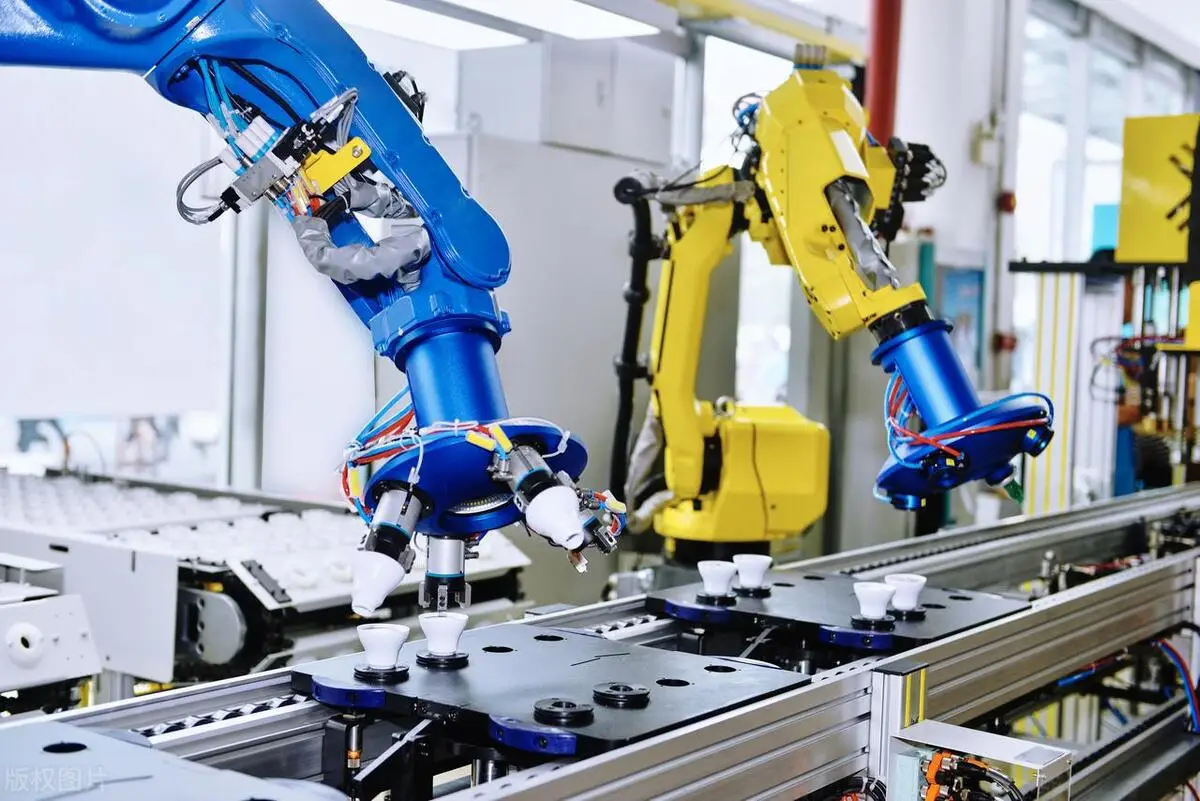

Application Scenario

Industrial robots: Suitable for various industrial robot joints, providing stable power output.

Automated assembly line: Provide flexible motion support for various automated equipment to ensure efficient operation of the production line.

Small mobile platform: Ideal for tools or transport equipment that require flexible movement and can effectively carry medium loads.

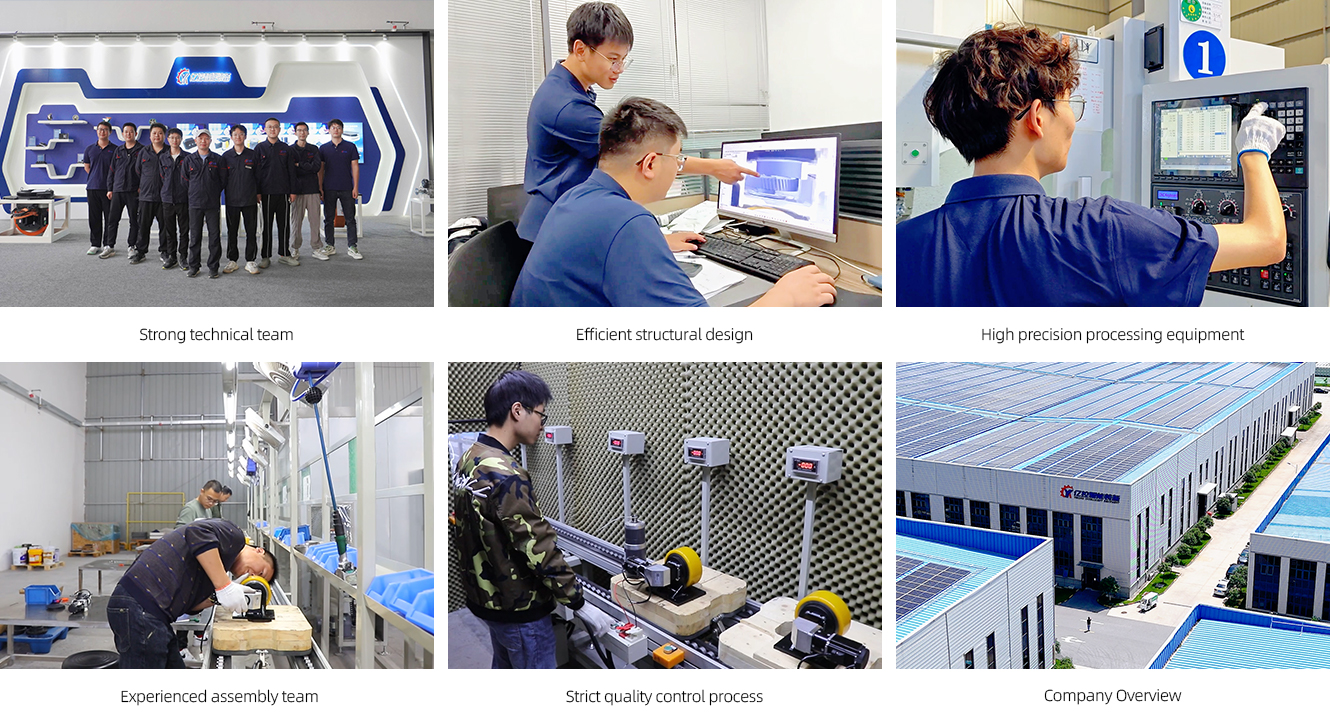

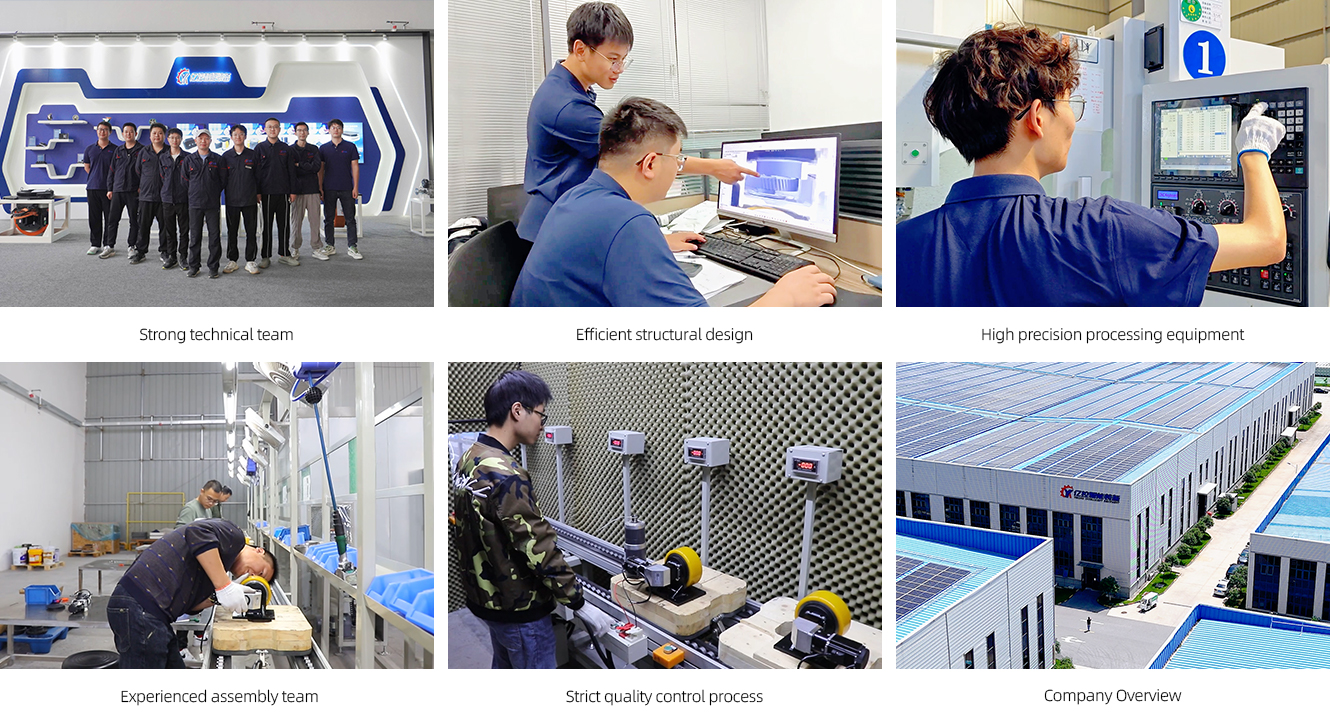

Six quality assurances

Product parameters (specifications)

| model | Rated voltage(V) | power(W) | Rated current(a) | speed(RPM) | Rated torque(NM) | Reduction ratio(I) | Output torque(NM) | Maximum Torque(NM) | Maximum load(kg) |

| TEC -167 | 24 | 400 | 18.4 | 3000 | 1.27 | 21 | 23 | 69 | 800 |

| 24 | 400 | 18.4 | 3000 | 1.27 | 32 | 35 | 105 | 800 |

| 48 | 750 | 18 | 3000 | 2.4 | 21 | 40 | 120 | 800 |

| 48 | 1000 | 26.4 | 3000 | 3.18 | 32 | 88 | 240 | 800 |

| TEC -210 | 48 | 3000 | 68 | 3000 | 9.55 | 32 | 260 | 576 | 1500 |

| TEC-220 | 48 | 750 | 18 | 3000 | 2.4 | 28 | 58 | 174 | 1000 |

| 48 | 750 | 18 | 3000 | 2.4 | 40 | 82 | 246 | 1000 |

| 48 | 1000 | 26.4 | 3000 | 3.18 | 40 | 102 | 306 | 1000 |

| TEC -250 | 48 | 1500 | 35 | 2000 | 7.16 | 27 | 165 | 480 | 1600 |

| 48 | 1500 | 35 | 2000 | 7.16 | 40 | 245 | 735 | 1600 |

| 48 | 2000 | 50 | 2000 | 9.55 | 27 | 220 | 480 | 1600 |

| 48 | 2000 | 50 | 2000 | 9.55 | 40 | 325 | 880 | 1600 |

| TEC -280 | 48 | 2500 | 55 | 2000 | 11.9 | 28 | 284 | 872 | 2000 |

| 48 | 2500 | 55 | 2000 | 11.9 | 40 | 405 | 1040 | 2000 |

| TEC -300 | 48 | 3000 | 74 | 2500 | 12 | 21 | 214 | 642 | 3000 |

| 48 | 3000 | 74 | 2500 | 12 | 40 | 408 | 1080 | 3000 |

| 48 | 4000 | 96 | 2500 | 15 | 21 | 268 | 780 | 3000 |

| 48 | 4000 | 96 | 2500 | 15 | 40 | 510 | 1080 | 3000 |

FAQ

Regularly check the working environment and lubrication system of the drive wheel, keep it clean, and avoid overloading to ensure long-term and stable operation.

Our drive wheels are particularly suitable for medium load applications and perform well in dynamic environments.

Its parallel axis structure enables the drive wheel to maintain stable movement in multiple directions, suitable for complex application environments.