Product Introduction

TEC series vertical drive wheel with steering is a high-performance drive solution designed for AGV (automatic guided vehicle) and industrial robots. Its compact structure and extremely small turning radius design ensure flexible movement in space-constrained scenarios. It uses high-quality materials and advanced manufacturing processes.

1. Bevel gear transmission structure, compact structure, low noise, and high output torque;

2. Vertical drive wheel series (named by wheel diameter mm): 150, 230, 250, 310, 343, 406, 457, 470 series application coverage.

3. Load range: 500kg-6500kg series;

4. 12V-96V input voltage range, vertical with steering/without steering;

5. Optional polyurethane wheel or rubber wheel structure;

6. Optional DC brush, AC asynchronous, permanent magnet servo motor, power range 400W-16KW;

7. Optional parts: shock-absorbing spring, limit switch, original switch, incremental/absolute encoder, potentiometer and other components.

8. Custom series: explosion-proof drive wheel, low temperature drive wheel, high IP protection level.

With excellent performance and multi-scenario adaptability, TEC series vertical drive wheel with steering is widely used in various automation equipment, helping enterprises to achieve efficient logistics and precise navigation.

Application Scenario

· Forklift: The compact design of the vertical drive wheel makes the forklift more compact, flexible and easier to operate.

Automated Guided Vehicles (AGVs): Ideal for automating material handling within factories. Their compact design and high maneuverability allow them to navigate narrow aisles with ease, while their powerful motors ensure they can handle a wide range of loads.

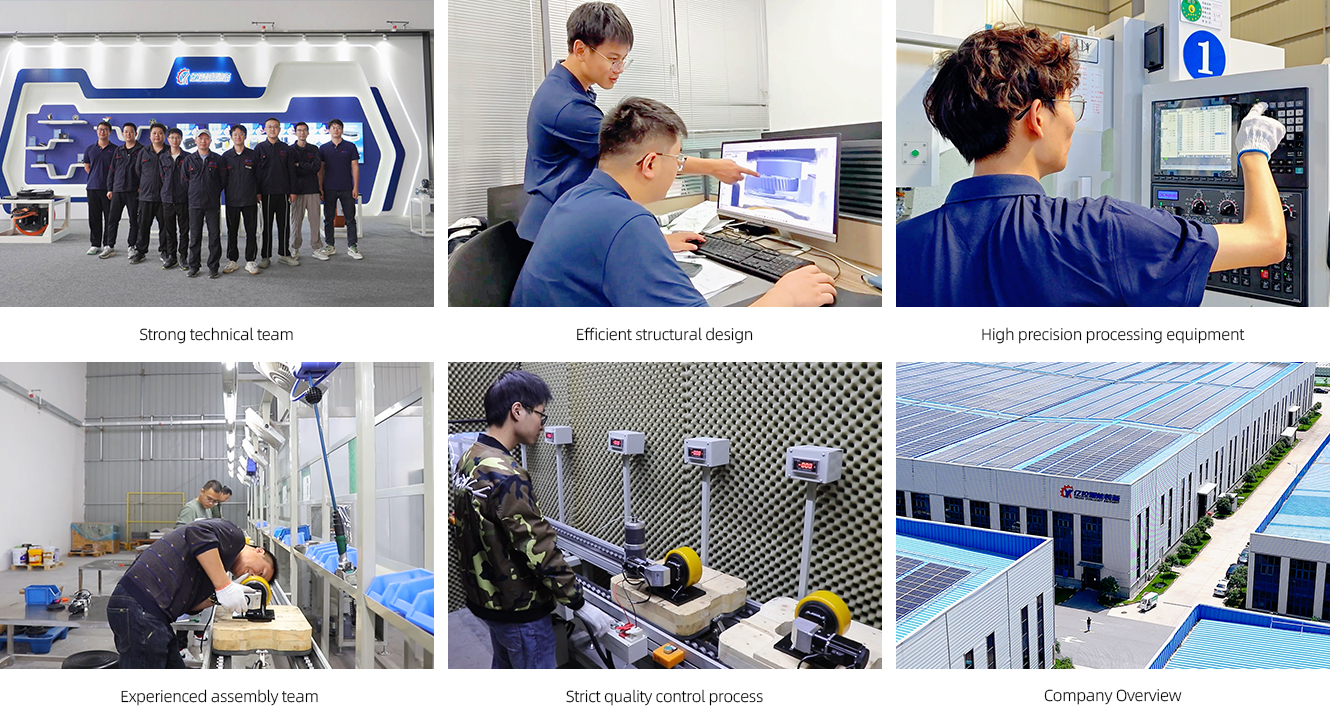

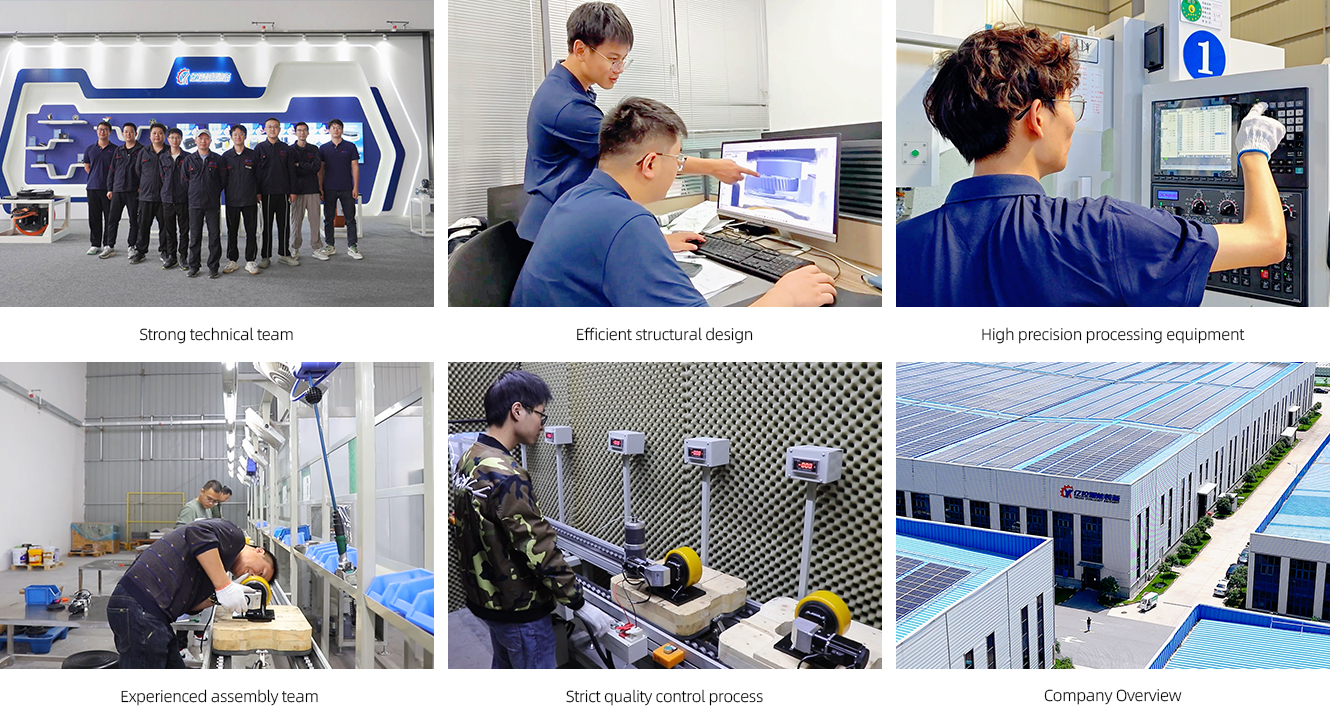

Six quality assurances

Product Specifications

| Walking part | Steering part |

| series | Rated voltage(V) | Electric Motor(W) | Rated current(A) | speed(RPM) | Rated torque(NM) | Reduction ratio(i) | Output torque(NM) | Maximum Torque(NM) | Maximum load(kg) | Rated voltage(V) | Electric Motor(W) | Rated current(a) | speed(RPM) | Rated torque(NM) | Reduction ratio(i) | Output torque(NM) |

| TEC-150 | 48 | 750 | 20 | 3000 | 2.4 | 22.5 | 45.9 | 114 | 500 | 48 | 200 | 6.4 | 3000 |

| 40 | 30 |

| TEC -230 | 24 | 1500 | 76 | 2590 | 5.5 | 30 | 108 | 300 | 1500 | 24 | 650 | 36 | 3487 | 1.78 | 50 | 71.2 |

| 24 | 1500 | 76.2 | 3200 | 4.5 | 30 | 108 | 300 | 1500 | 24 | 400 | 24 | 3000 | 1.27 | 33.92 | 34.4 |

| 24 | 1500 | 76.2 | 3200 | 4.5 | 30 | 108 | 300 | 1500 | 24 | 400 | 24 | 3000 | 1.27 | 33.92 | 34.4 |

| 48 | 1500 | 34 | 2500 | 5.73 | 30 | 145 | 365 | 1500 | 48 | 400 | 9.9 | 3000 | 1.27 | 50 | 42 |

| TEC -250 | 24 | 1600 | 100 | 2400 | 6.4 | 19 | 103 | 260 | 1800 | 24 | 650 | 36 | 3487 | 1.78 | 50 | 71.2 |

| 24 | 1600 | 100 | 2400 | 6.4 | 19 | 103 | 260 | 1800 | 24 | 400 | 24 | 3000 | 1.27 | 33.92 | 34.4 |

| 48 | 1600 | 35 | 2500 | 6.11 | 19 | 98.6 | 246 | 1800 | 48 | 400 | 9.9 | 3000 | 1.27 | 50 | 42 |

| 48 | 2500 | 63 | 2500 | 9.55 | 19 | 163 | 450 | 1800 | 48 | 400 | 9.9 | 3000 | 1.27 | 50 | 42 |

| TEC -310 | 24 | 3000 | 137 | 2500 | 11.46 | 23 | 224 | 650 | 2200 | 24 | 600 | 38.5 | 2275 | 2.52 | 45 | 95.6 |

| 48 | 3000 | 68 | 2500 | 11.5 | 23 | 224 | 650 | 2200 | 48 | 600 | 15 | 2500 | 2.3 | 50 | 108 |

| TEC -343 | 48 | 6500 | 180 | 2800 | 23 | 20.2 | 395 | 988 | 3200 | 48 | 1200 | 33 | 3000 | 3.82 | 50 | 191 |

| TEC -406 | 48 | 8000 | 207 | 1420 | 54 | 24 | 1054 | 2592 | 6000 | 48 | 2000 | 57 | 3000 | 6.4 | 50 | 305 |

| TEC -457 | 80 | 10000 | 142 | 1200 | 85 | 23.32 | 1684 | 4507 | 6500 | 80 | 3000 | 43 | 1500 | 19 | 50 | 305 |

| TEC -470 | 80 | 10000 | 142 | 1200 | 85 | 23.32 | 1684 | 4507 | 6500 | 80 | 3000 | 43 | 1500 | 19 | 50 | 305 |

FAQ

When shipping, we include the installation and wiring manual in the package. If you have difficulty in understanding, please feel free to contact our technical team, we will provide online technical support.

Vertical drive wheel:

o Application scenario: suitable for small spaces, such as narrow passages, allowing flexible steering.

o Load requirements: usually suitable for lighter loads.

o Steering flexibility: high maneuverability, easy to operate in narrow areas.

Horizontal drive wheel:

o Application scenario: suitable for environments that require stability and load-bearing capacity, such as heavy-load transportation.

o Load requirements: usually able to support heavier items.

o Steering flexibility: suitable for applications that require smooth operation.

Dual drive wheels are a type of wheel structure equipped with two independent drive systems, commonly used in automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). Each drive wheel can be controlled independently to achieve precise steering, increased flexibility and enhanced stability. They are particularly suitable for applications that require high-precision motion control, especially in space-constrained areas where the vehicle needs to perform pivot turns or effectively navigate complex paths.