TEC high-efficiency DC motors are designed for high-precision speed control in industrial robots and mobile devices. Customization is supported.

Previous article

No more

Jiangsu Yikong Intelligent Equipment Co., Ltd. and its wholly-owned subsidiary Shanghai Tongpu Electric Power Technology Co., Ltd. were jointly founded by a team of doctoral students from Tongji University with rich industry management experience in the field of "high-tech...

TEC high-efficiency DC motors are designed for high-precision speed control in industrial robots and mobile devices. Customization is supported.

Product Introduction

DC motors are widely used in industrial and mobile robots due to their precise speed control and high starting torque. Our DC motors are manufactured with advanced electromagnetic design and high-quality materials to ensure stable power output and efficient energy utilization. Their simple control method facilitates integration into various automation systems.

Application Scenario

Mobile Robots: DC motors are widely used in the drive systems and motion control of AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) due to their fast starting torque and flexible speed regulation.

Unmanned transport vehicles: In transport robots in warehouses and factories, DC motors provide a reliable source of power, ensuring precise movement in complex environments.

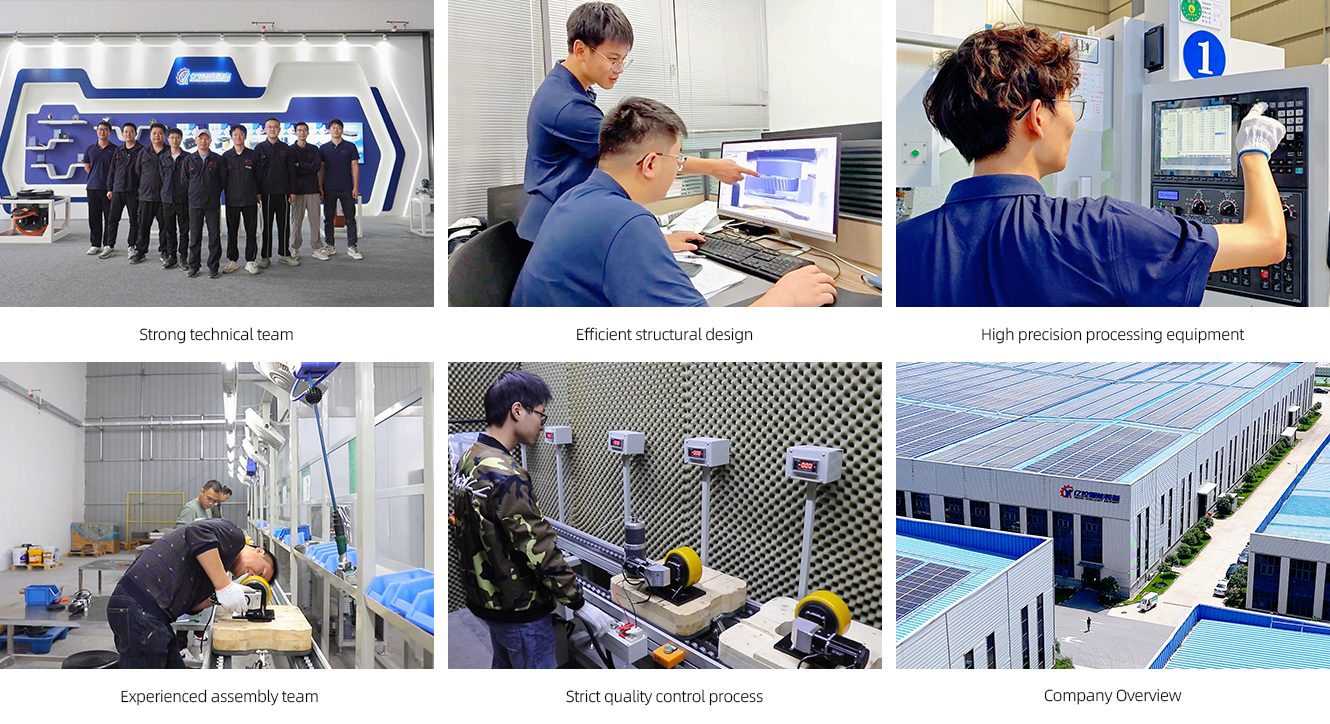

Six quality assurances

Product parameters (specifications)

Product Model | TEC-75 | TEC-85 | |||||||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

power (kW) | 0.1 | 0.15 | 0.15 | 0.25 | 0.4 | 0.55 | |||||||||||

Rated torque (Nm) | 0.96 | 0.64 | 0.48 | 0.32 | 0.96 | 0.72 | 0.48 | 1.43 | 2.39 | 1.59 | 1.19 | 0.8 | 2.55 | 1.91 | 1.27 | 2.63 | 1.75 |

Rated speed (r/min) | 1000 | 1500 | 2000 | 3000 | 1500 | 2000 | 3000 | 1000 | 1000 | 1500 | 2000 | 3000 | 1500 | 2000 | 3000 | 2000 | 3000 |

Rated voltage (V) | 24 | 24 | |||||||||||||||

Rated current (A) | 5.7 | 8.2 | 7.5 | 13 | 20 | 28 | |||||||||||

Peak Torque (Nm) | 8 | 5 | 4 | 3 | 8 | 6 | 4 | 9 | 15 | 10 | 8 | 5 | 16 | 12 | 8 | 16 | 11 |

Rotor resistance (Ω 20°C) | 0.6 | 0.4 | 0.6 | 0.3 | 0.4 | 0.2 | 0.3 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

Rotor inductance (mH) | 1.3 | 0.8 | 0.8 | 0.4 | 0.8 | 0.4 | 0.4 | 1 | 1 | 0.6 | 0.4 | 0.2 | 0.4 | 0.3 | 0.2 | 0.2 | 0.2 |

Torque constant (Nm/A) | 0.18 | 0.13 | 0.09 | 0.07 | 0.13 | 0.09 | 0.07 | 0.17 | 0.2 | 0.13 | 0.09 | 0.07 | 0.12 | 0.09 | 0.07 | 0.1 | 0.08 |

Back EMF Constant (V/kr/min) | 18 | 14 | 10 | 7 | 14 | 10 | 7 | 18 | 20 | 14 | 10 | 7 | 13 | 10 | 7 | 10 | 8 |

Rotor inertia (Kgm2 x10^-4) | 286.2 | 286.2 | 143.1 | 143.1 | 286.2 | 286.2 | 143.1 | 790 | 1027 | 790 | 553 | 553 | 1027 | 790 | 553 | 1027 | 790 |

Mechanical time constant (ms) | 6 | 5.9 | 9.2 | 8.6 | 5.9 | 5.7 | 8.6 | 5.2 | 4.7 | 5.8 | 6.9 | 7.5 | 4.7 | 5.3 | 7.5 | 4.4 | 6.9 |

Electrical time constant (ms) | 2.1 | 2.2 | 1.4 | 1.5 | 2.2 | 2.2 | 1.5 | 5.3 | 5.9 | 4.6 | 3.6 | 3.3 | 5.7 | 5 | 3.3 | 5 | 4 |

Theoretical maximum acceleration (Rad/s2) | 20103 | 26351 | 23548 | 36097 | 26351 | 37902 | 36097 | 23331 | 23165 | 26507 | 31345 | 41042 | 35164 | 41024 | 41042 | 49227 | 39387 |

weight (kg) | 2 | 2 | 1.5 | 1.5 | 2 | 2 | 1.5 | 4 | 6 | 5 | 4 | 4 | 6 | 5 | 4 | 6 | 5 |

FAQ

The DC motor is used in conjunction with a PWM controller to achieve precise speed regulation to meet the needs of various mobile robot movements.

The torque output of the motor can be improved by increasing the number of winding turns or using high-performance magnetic materials.

No more