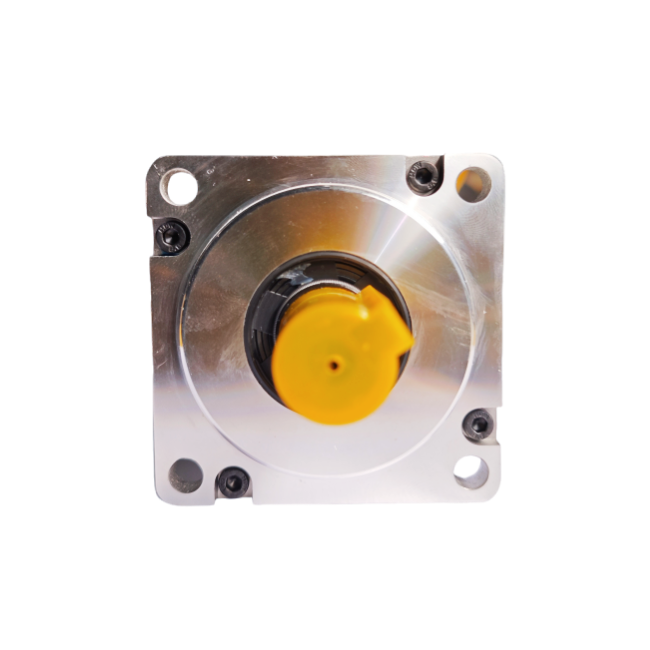

Product Introduction

Servo motors are known for their high efficiency and precise speed control, and are particularly suitable for applications that require fast response and high precision. The internal permanent magnet design enables servo motors to provide powerful output and reduce energy consumption while maintaining stable performance. Its excellent dynamic response characteristics make it perform well in complex motion control systems.

1. High overload, high speed, low torque fluctuation, low temperature rise, customizable, temperature range customized -40~50℃;

2. Design standards IEC 60072-1:1991, GT/T 4772.1-1999, insulation level (IEC 60034-1), cooling method (IEC 60034-6), vibration level (IEC 60034-14);

3. Motor flange series mm: 40, 60, 80, 110, 130, 180 and other customized flanges;

4. 12V-96V input voltage range;

5. Motor power range: 100W-12KW;

6. Optional components: incremental/absolute encoder, brake and other components;

7. Customized series: explosion-proof motor, low temperature motor, high IP protection level;

8. OEM customer customization.

Application Scenario

Autonomous Mobile Robots (AMRs): PMAC motors are widely used in AMRs, providing fast-response power output and efficient energy utilization, ensuring flexible operation in complex environments.

Industrial Robot Arms: PMAC motors provide high-precision position and velocity control in robotic joint systems for high-precision applications such as welding and assembly.

Collaborative Robots (Cobots): In collaborative robots, PMAC motors maintain low noise and high efficiency during complex tasks, making them ideal for human-machine interaction scenarios.

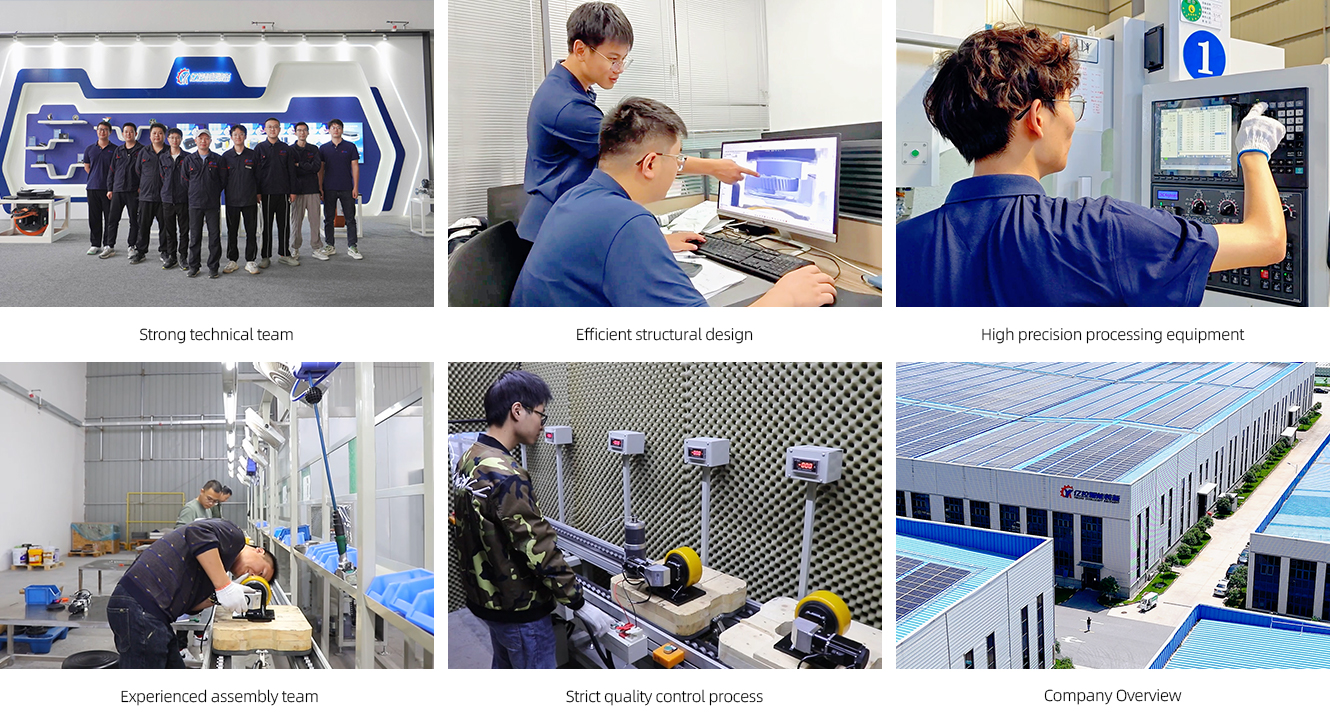

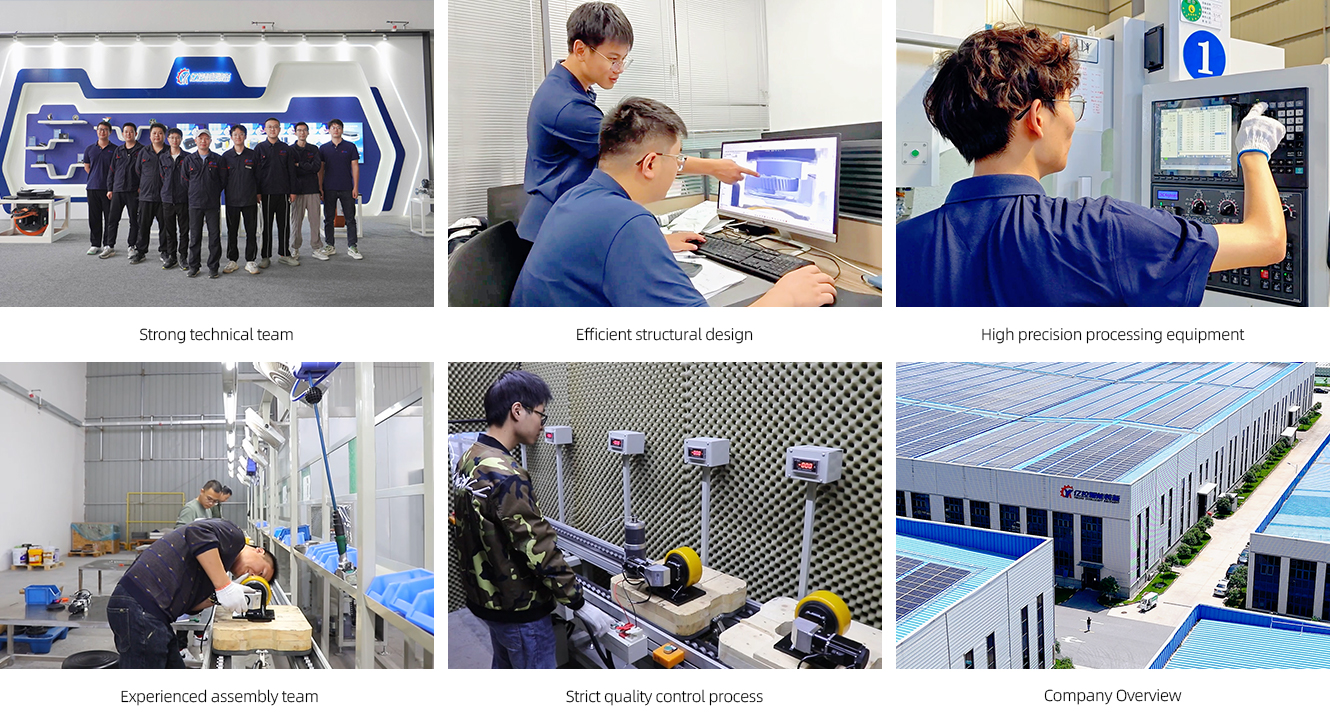

Six quality assurances

Product parameters (specifications)

Motor Model | Operating voltage (U) | Rated Power (W) | Rated torque Mn (Nm) | Rated speed Nn (rpm) | Maximum speed Nn (rpm) | Rated current (A) | Maximum current ( A) | Pole pairs P | Moment of Inertia I (kgcm²) | Torque constant K (Nm/A) | Back EMF Constant Ke (V/Krpm) | Motor Model |

TEC40 | 48VDC | 50 | 0.16 | 3000 | 3850 | 1.5 | 0.55 | 5.75 | 5 | 0.044 (0.05) | 0.132 | 8 |

48VDC | 100 | 0.32 | 3000 | 3850 | 2.9 | 1.1 | 11.5 | 5 | 0.074 (0.08) | 0.132 | 8 |

TEC60 | 48VDC | 200 | 0.64 | 3000 | 3850 | 5.8 | 1.92 | 18.2 | 5 | 0.26 (0.28) | 0.132 | 8 |

48VDC | 400 | 1.28 | 3000 | 3850 | 11.6 | 3.84 | 36.4 | 5 | 0.52 (0.54) | 0.132 | 8 |

48VDC | 600 | 1.91 | 3000 | 3850 | 17.4 | 5.73 | 54.5 | 5 | 0.72 (0.74) | 0.132 | 8 |

TEC80 | 48VDC | 750 | 2.4 | 3000 | 3850 | 19.6 | 7.2 | 62 | 5 | 1.33 (1.42) | 0.132 | 8 |

48VDC | 1000 | 3.18 | 3000 | 3850 | 27.5 | 9.55 | 83 | 5 | 1.81 (1.9) | 0.132 | 8 |

TEC130 | 48VDC | 1500 | 4.78 | 3000 | 3350 | 38.5 | 14.33 | 120 | 5 | 10 (11.3) | 0.14 | 8.6 |

48VDC | 2000 | 6.37 | 3000 | 3500 | 53 | 19.1 | 170 | 5 | 13.8 (15.1) | 0.136 | 8.2 |

48VDC | 2500 | 8 | 3000 | 3300 | 60 | 24 | 190 | 5 | 17.5 (18.8) | 0.147 | 8.9 |

48VDC | 3000 | 9.55 | 3000 | 3400 | 75 | 28.65 | 230 | 5 | 19.7 (21) | 0.141 | 8.5 |

TEC180 | 48VDC | 3000 | 14.33 | 2000 | 2150 | 74 | 43 | 230 | 5 | 42.5 | 0.227 | 13.71 |

48VDC | 4000 | 19.1 | 2000 | 2150 | 99 | 57.3 | 306 | 5 | 55 | 0.227 | 13.77 |

48VDC | 5000 | 23.88 | 2000 | 2150 | 125 | 71.64 | 383 | 5 | 63 | 0.22 | 13.33 |

48VDC | 6000 | 28.65 | 2000 | 2150 | 152 | 57.3 | 304 | 5 | 83 | 0.21 | 12.67 |

48VDC | 7500 | 35.81 | 2000 | 2150 | 180 | 71.62 | 360 | 5 | 115 | 0.223 | 13.5 |

FAQ

PMAC motors can achieve micron-level accuracy in motion control by integrating with high-precision sensors and controllers, making them suitable for high-precision tasks in industrial applications.

Due to its brushless design, PMAC motors require less maintenance. However, regular inspection of the bearings and cooling system is recommended to ensure long-term stability.

PMAC motors have fast dynamic response and precise motion control, and are particularly suitable for mobile robots that require frequent acceleration, deceleration, and direction changes.