Product Introduction

Brushed DC drivers can precisely control DC motors by adjusting voltage or using pulse width modulation (PWM) signals, and are suitable for a variety of small applications. The driver has fast response characteristics and can quickly change the speed and direction of the motor, thereby improving overall work efficiency.

Key highlights

1. Control mode: supports position, speed, and torque control modes, and is suitable for AGV basic linear handling and fixed-site docking.

2. Communication protocol: compatible with CANopen, EtherCAT and other protocols, seamlessly connected to AGV navigation and scheduling systems.

3. Encoder adaptation: fully compatible with photoelectric, magnetic, and absolute encoders to meet high-precision positioning requirements.

4. Motor drive: adapted to 500W~20kW low-voltage servo motors, covering light load to industrial-grade heavy load scenarios.

5. Two-in-one drive (drive + energy management), emergency alarm braking, battery life optimization; supports customized development of working conditions (such as explosion-proof, extreme temperature resistance, and impact resistance).

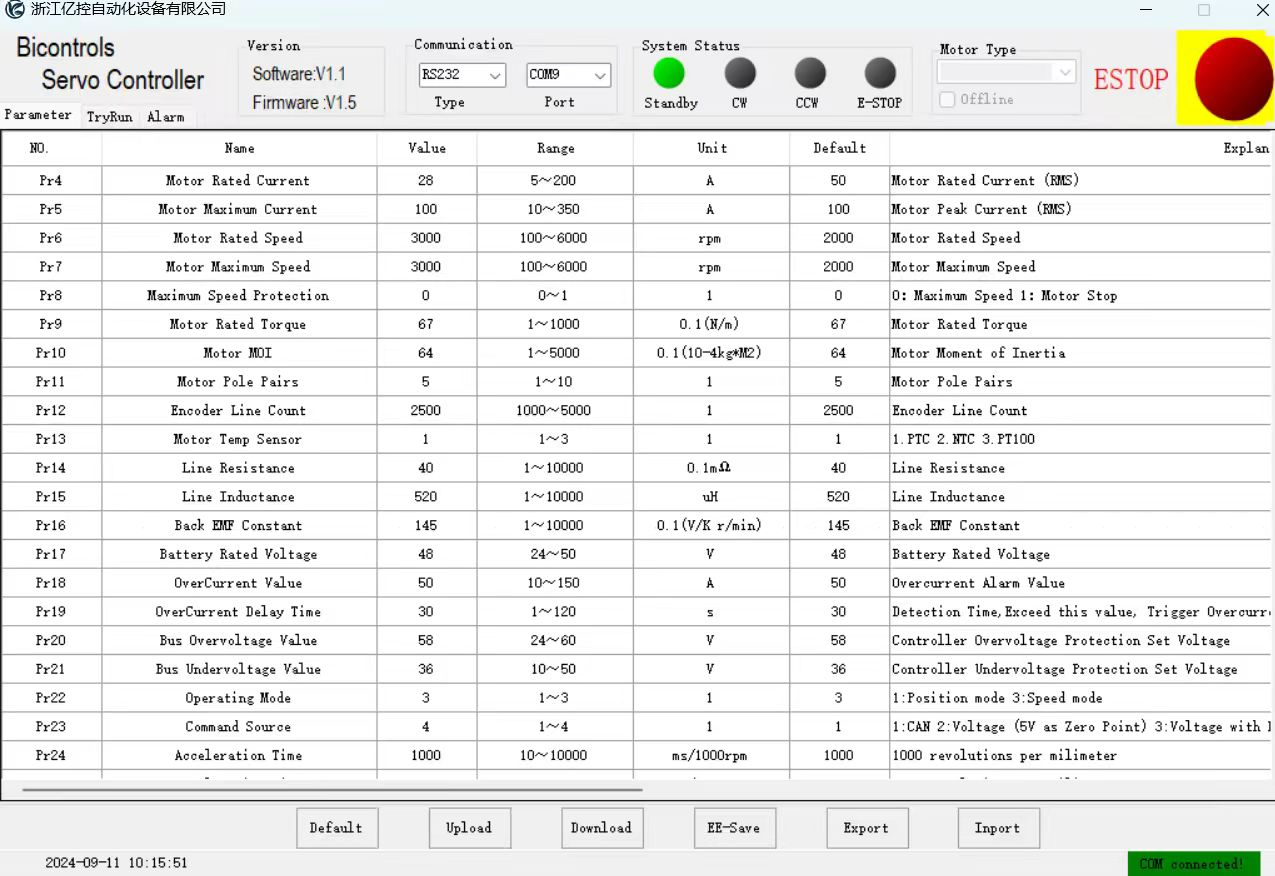

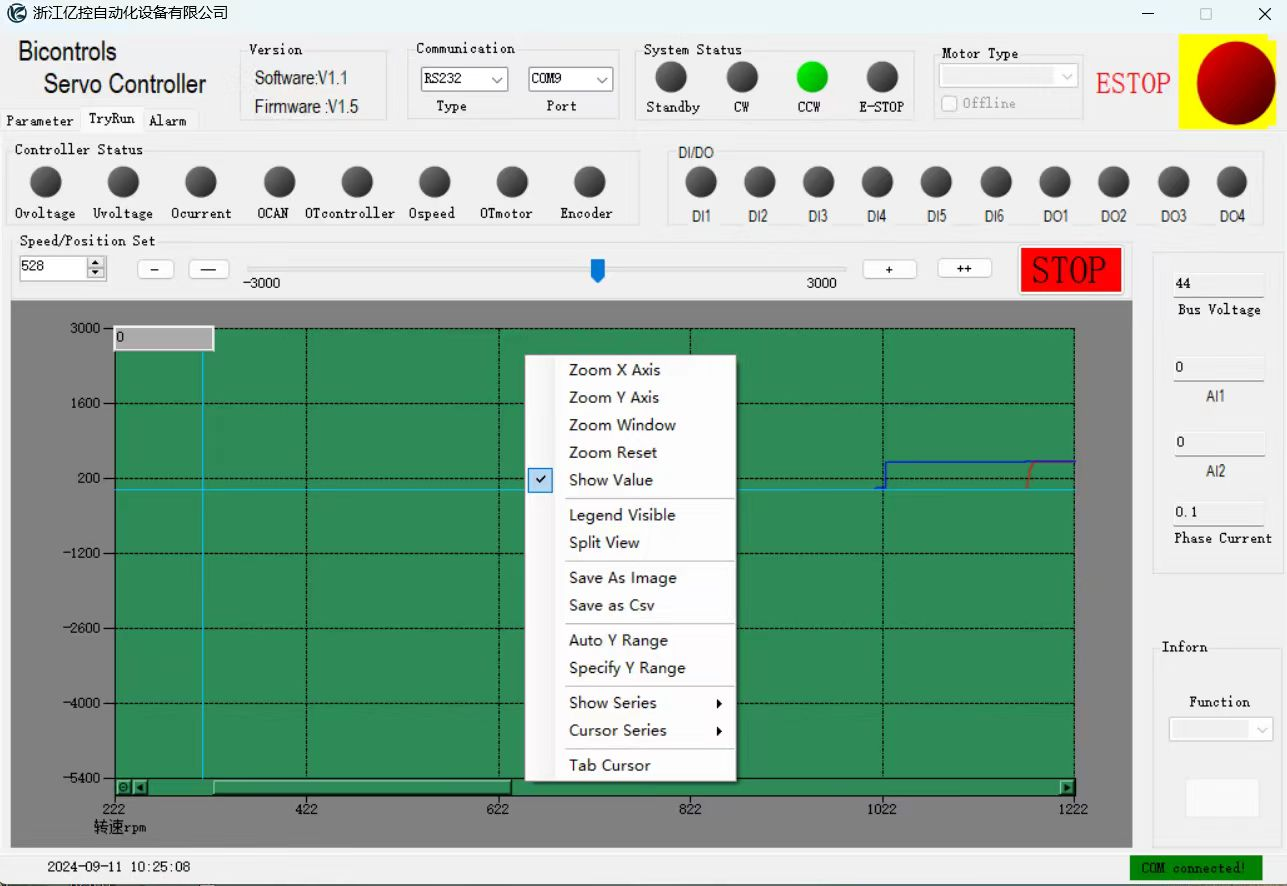

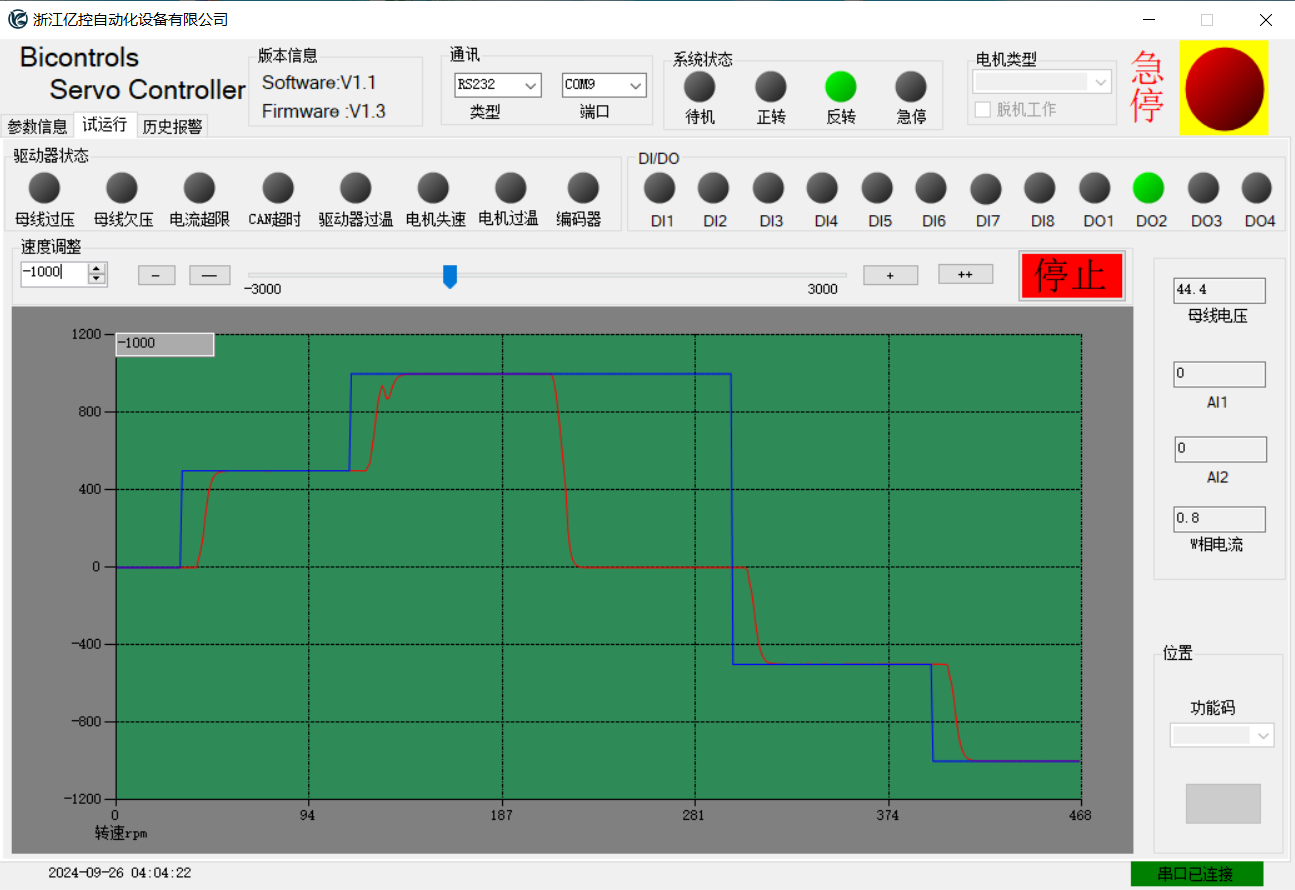

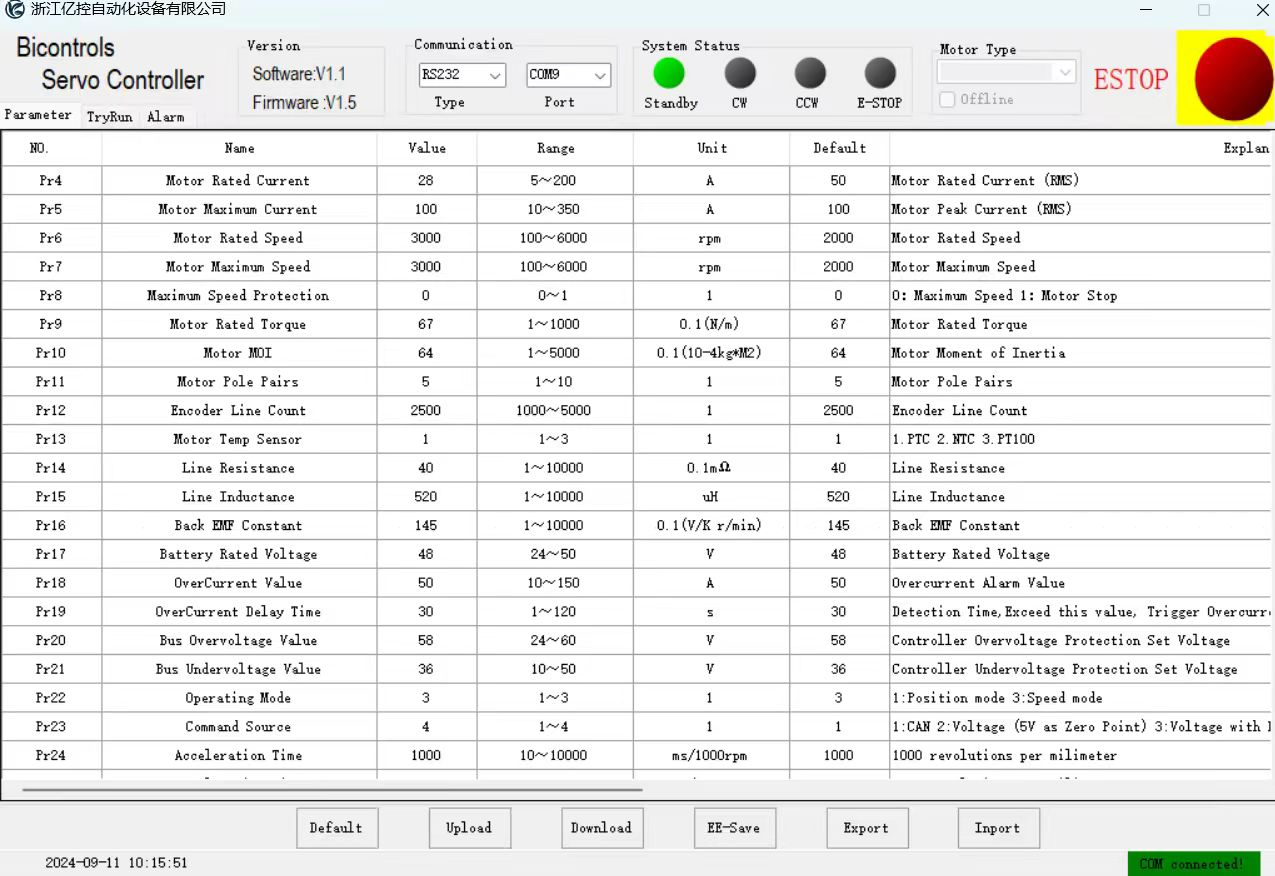

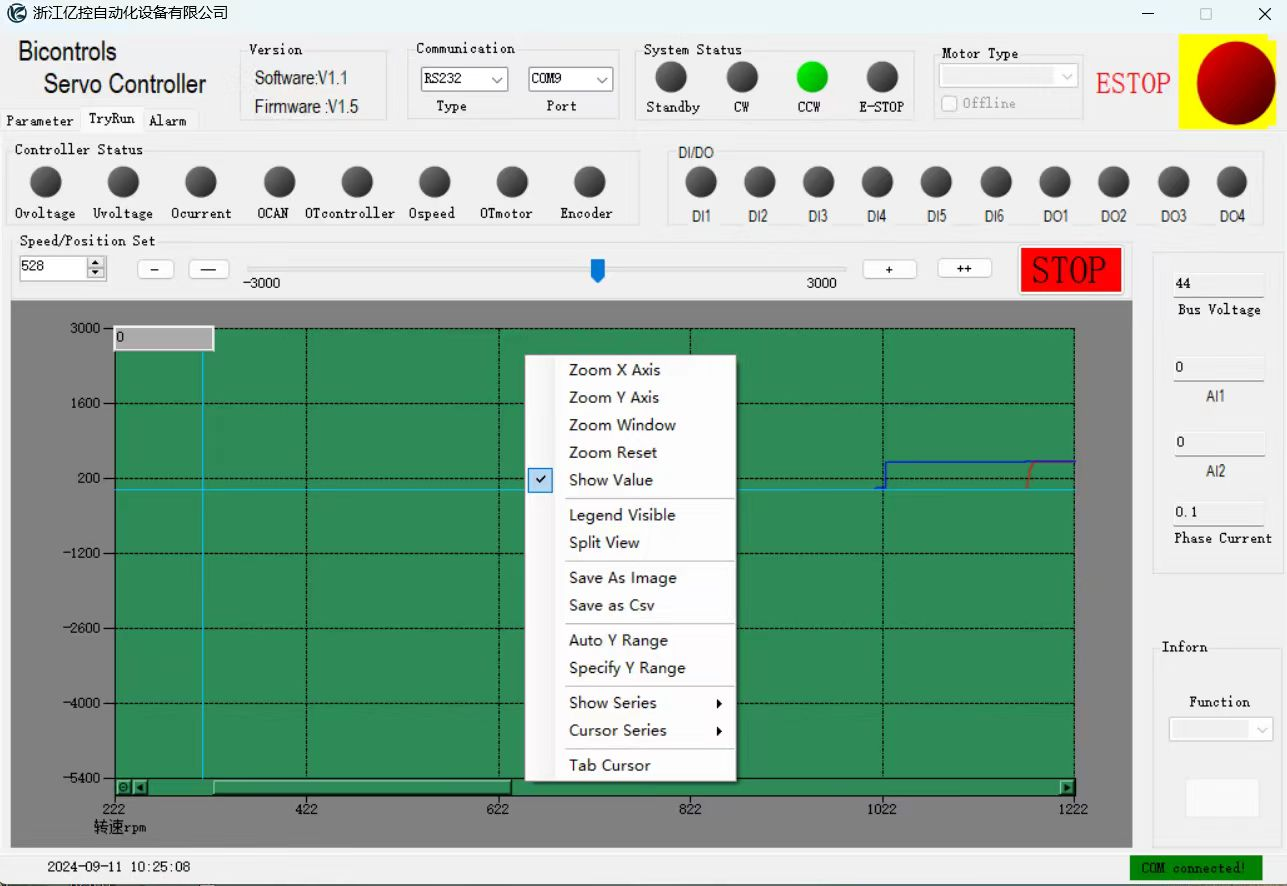

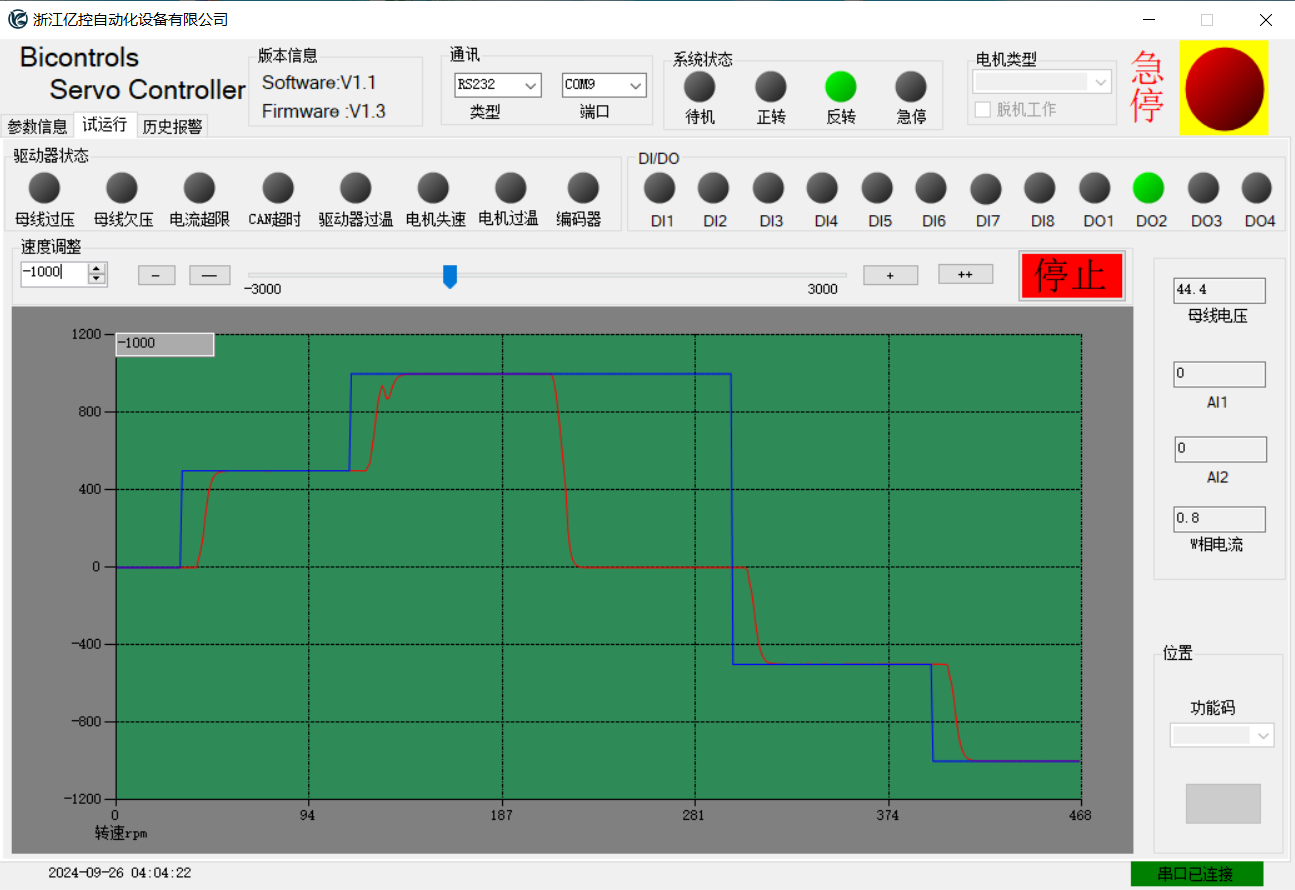

6. Supporting software: The interface is simple and clear, with 0.1-level accuracy to display voltage, current, DI/DO status, millisecond-level real-time curve tracking instructions and feedback; parameter step adjustment (±1/±10), alarm record loop storage, convenient and precise debugging.

Application Areas

1. Light load handling: warehouse fixed route pallet AGV (average 8 hours of basic transportation per day).

2. Short-distance guidance scenarios: shopping mall guide robots, light file transfer AMR (<500kg load).

Six quality assurances

Product parameters (specifications)

| Basic parameters | TEC-DCH-I-U | TEC-DCM-I-U | TEC-DCL-I-U |

| Electrical parameters | Voltage | DC 12-72 |

| Rated current | 150A | 50A | 25A |

| control | Control method | 1: Speed closed loop control | 1: Speed closed loop control |

| 2: Position closed loop control |

| Input and output interface | Analog input | 1 channel 0-10V analog | 2 channels 0-10V analog |

| Digital input | 5 digital inputs, low level valid | 8 digital inputs, low level valid |

| Digital output | 3 open collector outputs | 2 open collector outputs |

| 12V output | 1 12V power output, maximum current 200mA |

| Feedback | Encoder | 5V, incremental differential input |

| communication | USB | USB connection to host computer software |

| CAN | Standard CANopen protocol |

FAQ

Depending on the conditions of use, the life of a DC drive is usually more than 5 years, and it is suitable for application scenarios that require long-term stable operation.

Speed control can be achieved by adjusting the voltage, PWM signal or changing the power supply frequency.

The output power of DC drives can range from a few watts to several kilowatts, depending on the model and application.