Product IntroductionThe TEC Lifting and Rotating Mechanism is designed for high

Previous article

No more

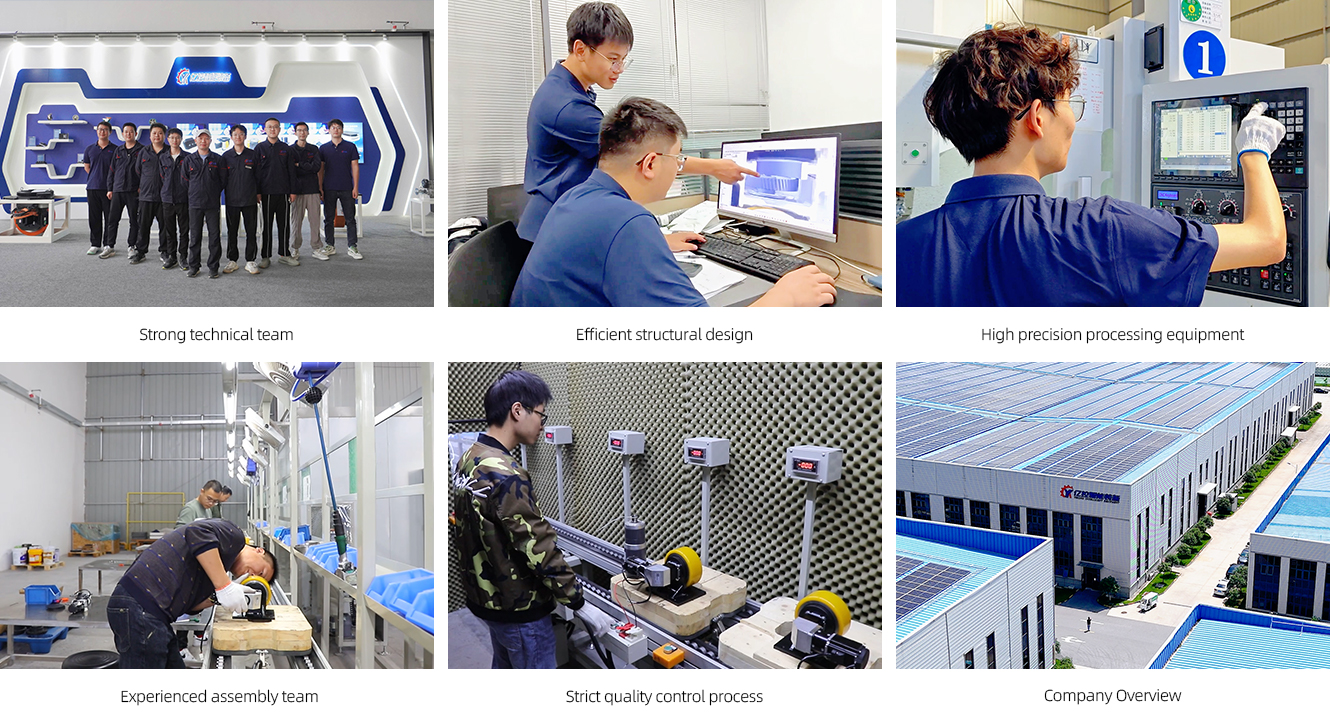

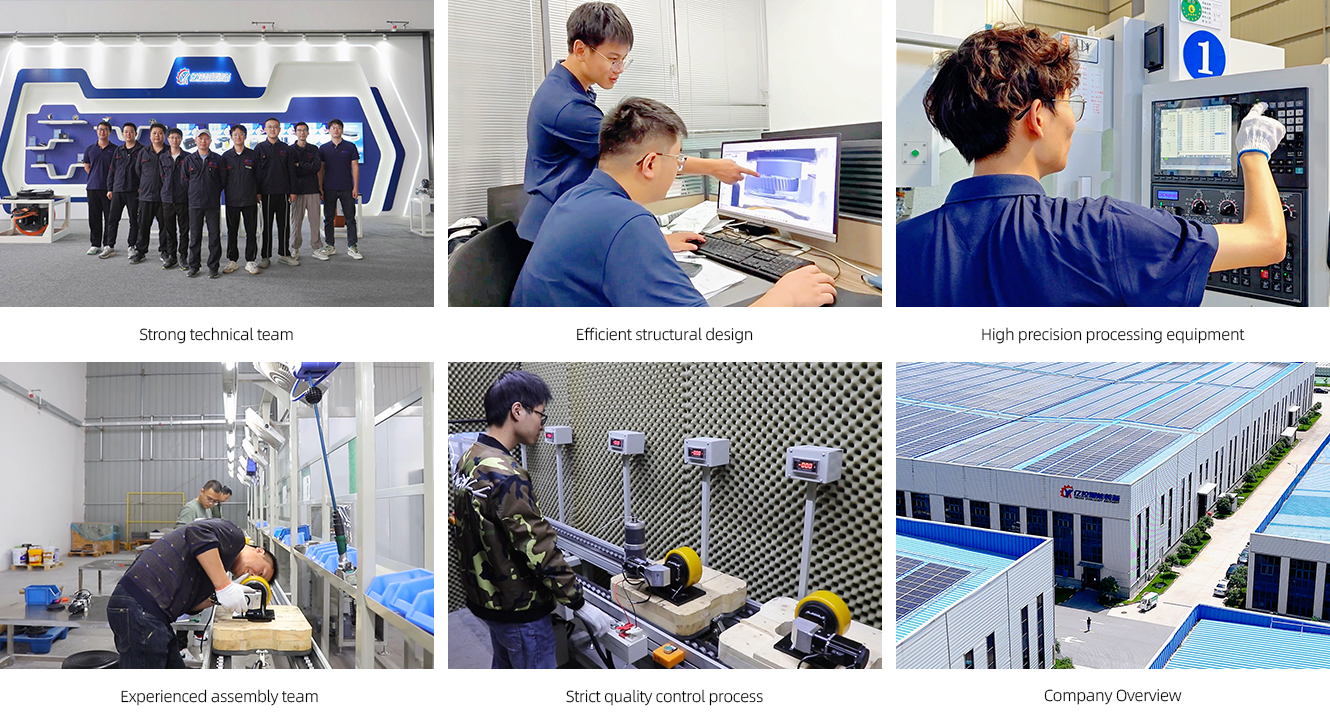

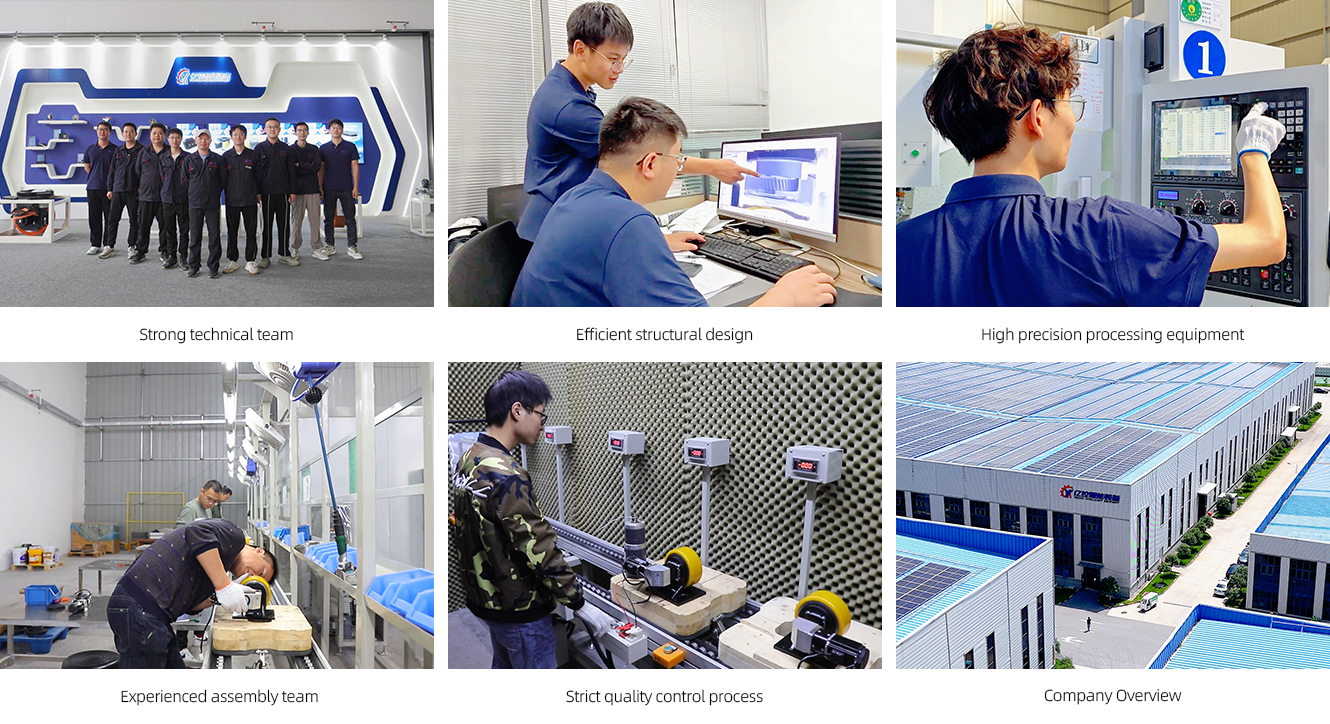

Jiangsu Yikong Intelligent Equipment Co., Ltd. and its wholly-owned subsidiary Shanghai Tongpu Electric Power Technology Co., Ltd. were jointly founded by a team of doctoral students from Tongji University with rich industry management experience in the field of "high-tech...

Product IntroductionThe TEC Lifting and Rotating Mechanism is designed for high

Product Introduction

The TEC Lifting and Rotating Mechanism is designed for high precision and reliability, offering a robust solution for heavy-duty industrial applications. Featuring a self-locking design, it ensures stability during power outages, while its optimized ball screw drive delivers accurate linear motion, ideal for tasks that require precise positioning. With a high load capacity of up to 300kg, it can easily handle both static and dynamic loads. The compact design allows for flexible installation in limited spaces, and it supports various motor configurations to meet diverse power needs. Built with advanced materials, it guarantees long-lasting performance and high stability.

Application Scenario

Industrial Automation Equipment

Used for equipment adjustment and workpiece positioning on production lines, helping to improve efficiency and precision.

Logistics Systems

Provides high-load and high-precision lifting capability in stackers or material handling platforms, enhancing warehousing and logistics efficiency.

Vehicle and Equipment Maintenance

Provides safe and reliable lifting support for vehicle workstations or equipment maintenance.

Six quality assurances

Product Specifications

| Model | TEC-DSJG300 | TEC-DSJG500 | TEC-DSJG1000 | TEC-DSJG1500 |

| Motor Type | 永磁同步伺服电机 | |||

| Power [W] | 400 | 400 | 600 | 1000 |

| Voltage [V] | 48 | 48 | 48 | 48 |

| Current [A] | 11.95 | 11.95 | 16.5 | 26.4 |

| Speed [rpm] | 3000 | 3000 | 3000 | 3000 |

| Rated Torque [Nm] | 1.27 | 1.27 | 1.91 | 3.18 |

| Peak Torque [Nm] | 64 | 3.2 | 4.78 | 7.95 |

| Lifting Capacity [kg] | 300 | 500 | 1000 | 1500 |

| IP Rating | 65 | 65 | 65 | 54 |

| Stroke [mm] | 60 | 60 | 60 | 60 |

| Reduction Gear Ratio [I] | 30 | 30 | 30 | 40 |

| Screw Drive Ratio [I] | 6 | 8.3 | 10 | 5.3 |

| 90° Rotation Time [s] | 1 | 1.5 | 1.3 | 2.6 |

| Thread Specification [mm] | T25x5 | T32x5 | T35x6 | T45x6 |

| Lifting Speed [mm/s] | 8.36 | 8.3 | 10 | 7.5 |

| Lifting Time [s] | 7.2 | 7.2 | 6 | 8 |

| Limit Sensor | NPN | NPN | NPN | NPN |

| Lifting Structure Total Weight [Kg] | 25 | 35 | 50 | 90 |

| Number of Motors | 1 | 2 | 2 | 2 |

FAQ

Product Introduction

Our explosion-proof drive wheels are manufactured using specialized materials and advanced processes to ensure superior safety performance in high-risk environments. Designed specifically for explosion-proof applications, it effectively prevents sparks and potential hazards, ensuring reliable operation in flammable and explosive environments. The wheel's rugged structure and high-strength materials ensure durability and stability under extreme conditions such as high temperature and pressure, making it an ideal choice for workplaces with strict safety requirements. Each drive wheel is fully tested and quality controlled to ensure long-lasting protection and reliable performance in harsh industrial environments.

Application Scenario

1. Chemical plants and oil platforms: Ideal for use in flammable and explosive environments, ensuring safe and efficient power transmission.

2. Mining equipment: Provide safe and stable performance in high-risk mining and underground operations, ensuring reliable and harmless driving power.

3. Hazardous Goods Storage Equipment: Perfectly suited for automated machinery handling hazardous chemicals and flammable materials, preventing sparks and ensuring safe operation.

Six quality assurances

Product Introduction

Our cryogenic drive wheels use special cryogenic materials and advanced manufacturing processes to ensure excellent performance in harsh environments. Designed specifically for cryogenic motors, this drive wheel can maintain stable operation in extreme climate conditions from -40℃ to -60℃, ensuring equipment reliability. Its rugged structure and high-strength materials guarantee durability and stability in extreme low-temperature conditions, making it suitable for polar operations, refrigerated transportation, and other cold weather applications. Each cryogenic drive wheel undergoes rigorous testing and quality control to ensure lasting performance in harsh environments.

Application Scenario

Polar operations: Suitable for extreme low temperature environments such as the Arctic and Antarctic, providing stable power for scientific research and exploration equipment.

Refrigerated transportation: In refrigerated trucks and cold chain logistics, low-temperature drive wheels ensure that the equipment can operate normally in low-temperature environments.

.jpg)

Six quality assurances

Product Introduction

Electric steering wheels can be widely used in logistics handling equipment, automated production lines and other fields. In logistics handling, they can provide strong power and flexible steering capabilities for forklifts, transport trucks and other equipment, improving the efficiency and accuracy of cargo handling. On automated production lines, they can accurately control the movement and positioning of equipment to ensure the efficiency and stability of the production process. In addition, its higher load-bearing capacity enables it to meet the needs of heavy-duty equipment.

Application Scenario

Forklift:

Dual-wheel steering drive wheels provide forklifts with excellent maneuverability and stability. In narrow warehouse aisles, dual-wheel steering drive wheels can achieve a smaller turning radius, allowing forklifts to easily carry goods and operate flexibly in limited spaces. For example, in large logistics centers, forklifts equipped with dual-wheel steering drive wheels can quickly and accurately remove goods from shelves and deliver them to designated locations.

Trolleys:

Whether it is a manual or electric trolley, the dual-wheel steering drive wheel can improve its handling efficiency and operating convenience. In the cargo loading and unloading area, the trolley can adjust its direction more flexibly to adapt to different working environments. For example, in port cargo loading and unloading, the dual-wheel steering drive wheel can enable the trolley to efficiently carry cargo in crowded dock areas.

Automated production line:

In the automated production line, the dual-wheel drive wheel can accurately control the movement and positioning of the equipment to ensure the efficiency and stability of the production process. For example, in an automobile manufacturing plant, the dual-wheel drive wheel can carry robots or other automated equipment to move quickly between different production stations to improve production efficiency.

Six quality assurances

Product Introduction

Rubber drive wheels are usually made of high-quality rubber materials with good wear resistance, impact resistance and anti-slip properties. Such drive wheels can provide stable power transmission under various ground conditions to ensure the normal operation of the equipment.

Its design takes into account different application scenarios and is suitable for various industrial equipment, logistics handling equipment, etc. The rubber material can reduce noise and vibration, bringing a more comfortable experience to the operating environment.

In addition, the rubber drive wheel has good elasticity, can adapt to a certain degree of terrain changes, and can be used in conjunction with other components to provide reliable connection and transmission.

Application Scenario

Factory automation production line:

In various automated production lines, rubber drive wheels can be used to drive conveyor belts, roller conveyors and other conveying equipment. They can operate stably under different ground conditions in the factory to ensure the smooth transportation of products. For example, in automobile manufacturing plants, rubber drive wheels can drive automobile parts to move accurately to various assembly stations on the production line.

Industrial robots:

Some moving parts of industrial robots may use rubber drive wheels to achieve flexible movement and precise positioning. The good elasticity and anti-slip performance of rubber drive wheels can ensure the stable operation of robots in different working environments and improve production efficiency and quality.

Forklift:

Forklift is a commonly used equipment in logistics warehousing. The driving wheels of forklift are generally made of rubber. The rubber driving wheels can provide good grip and stability, allowing the forklift to transport goods safely and efficiently on different floors such as cement floors and epoxy floors in the warehouse.

Automated Guided Vehicle (AGV):

AGV is responsible for the automated transportation of goods in logistics warehouses. The rubber drive wheels can provide it with smooth driving performance and precise navigation control. The shock-absorbing effect of the rubber material can also protect the goods on the vehicle from damage.

Six quality assurances

Product Introduction

The TEC Lifting and Rotating Mechanism is designed for high precision and reliability, offering a robust solution for heavy-duty industrial applications. Featuring a self-locking design, it ensures stability during power outages, while its optimized ball screw drive delivers accurate linear motion, ideal for tasks that require precise positioning. With a high load capacity of up to 300kg, it can easily handle both static and dynamic loads. The compact design allows for flexible installation in limited spaces, and it supports various motor configurations to meet diverse power needs. Built with advanced materials, it guarantees long-lasting performance and high stability.

Application Scenario

Industrial Automation Equipment

Used for equipment adjustment and workpiece positioning on production lines, helping to improve efficiency and precision.

Logistics Systems

Provides high-load and high-precision lifting capability in stackers or material handling platforms, enhancing warehousing and logistics efficiency.

Vehicle and Equipment Maintenance

Provides safe and reliable lifting support for vehicle workstations or equipment maintenance.

Six quality assurances

No more