- By 小编

- 2025-06-19 11:10:37

- TECHNICAL

The Silent Revolution of Motor Technology in the New Energy Era

The Silent Revolution of Motor Technology in the New Energy Era

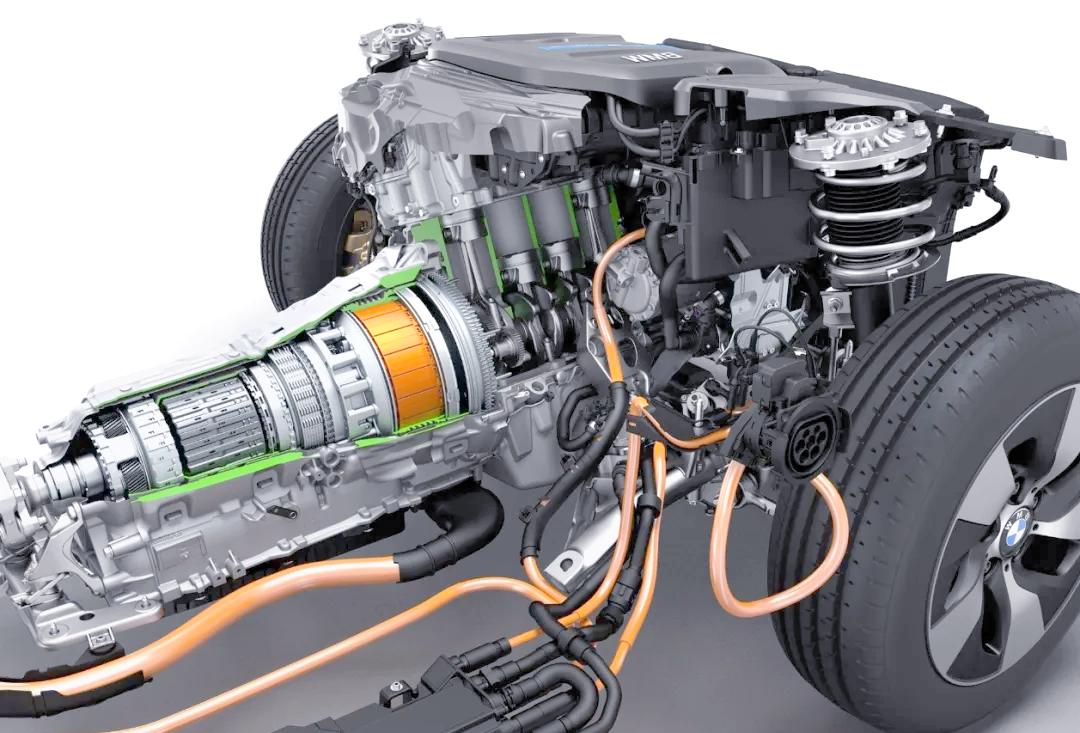

In today’s global wave of new energy vehicles and renewable energy, motor technology is undergoing a quiet revolution. While traditional radial flux motors still dominate thanks to their mature manufacturing processes, a new generation of axial flux motors is challenging the status quo. With disruptive design concepts, axial flux motors are breaking through the ceiling of power density, opening new possibilities for high-value industries.

.png)

1. A Shift in Magnetic Flux Paths: Axial vs. Radial

One of the core secrets of motor performance lies in its magnetic flux path design:

Axial Flux Motor (AFM):

The magnetic flux is aligned parallel to the motor’s shaft. The stator and rotor are arranged like pages of a book, yielding a thin, disc-shaped structure. The magnetic flux path is short and straight, passing directly across the air gap..png)

Radial Flux Motor (RFM):

The magnetic flux is oriented perpendicular to the shaft. The stator forms a sleeve around the cylindrical rotor, and the magnetic flux path must curve and close within the iron cores..png)

This fundamental difference gives rise to distinctly different performance characteristics:

| Dimension | Axial Flux Motor (AFM) | Radial Flux Motor (RFM) |

| Magnetic Flux Direction | Parallel to the shaft (axial) | Perpendicular to the shaft (radial) |

| Structural Features | Flat design, very short axial length | Cylindrical design, longer axial length |

| Power Density | Very high (torque ∝ outer diameter^3) | Moderate (torque ∝ outer diameter^2 × stack length) |

| Torque Characteristics | High torque at low speeds (large rotor diameter and long lever) | Torque varies more significantly with speed, often requires a reducer |

| Efficiency | Typically > 96% (short magnetic path, low losses) | Typically 90–95% |

| Cooling Challenges | Challenging (long cooling path, needs innovative solutions such as composite rotors and liquid cooling) | Simpler (short cooling path, mature cooling methods) |

| Cost & Manufacturing | Higher (complex manufacturing: precision assembly, carbon fiber, automated winding, challenging air-gap control) | Lower (mature manufacturing, cost-effective) |

| Typical Applications | High-end electric vehicles, direct-drive wind turbines, robot joints, drones, range extenders | Industrial motors, traditional electric vehicles, household appliances |

2. Axial Flux Motor: The Benchmark for High Density and Efficiency

The AFM’s flat design delivers unprecedented benefits:

Revolution in Space and Power Density:

By drastically compressing the axial length, AFMs unlock valuable installation space, making them ideal for electric vehicle platforms and robot joints. Torque scales with the cube of the outer diameter (versus the square for RFMs), allowing AFMs to deliver higher torque within the same volume or weight.Low-Speed, High-Torque Advantage:

AFM’s larger rotor diameter acts like a long lever, making it ideal for low-speed, high-torque applications such as electric vehicle starts or direct-drive wind turbines.Peak Efficiency:

With a nearly linear magnetic path, AFMs minimize iron losses and magnetic resistance, achieving efficiency levels exceeding 96%. This is highly valuable in applications where every percent of efficiency counts.Lightweight Leader:

Through structural optimization and the use of advanced materials (such as carbon-fiber-reinforced composite rotors), AFMs achieve significant weight reduction.

Yet, every coin has another side. The AFM’s long thermal path can lead to heat buildup, making innovative thermal management (e.g., integrated liquid cooling, high thermal conductivity composites) vital. Meanwhile, precision manufacturing techniques (such as automated disc winding and air-gap control) and the cost of special materials hamper large-scale adoption.

.png)

3. Radial Flux Motor: The Mature and Reliable Cornerstone

With decades of accumulated engineering expertise, RFMs remain the backbone of industry:

Mature and Stable:

Their cylindrical structure and laminated iron core design are highly standardized, making manufacturing and maintenance cost-effective.Excellent Cooling:

Short radial cooling paths and well-established thermal designs enable long-duration, high-load operation.Best Cost-Performance Ratio:

For mass-produced applications such as mid- to low-end electric vehicles, industrial drives, and household appliances, RFMs’ cost advantage is unmatched.

Their limitation lies in relatively lower torque density and larger size. Additionally, their torque output varies more significantly with speed, often necessitating a reducer for optimization.

.png)

4. The New Frontier: AFM’s Ascent

Today, AFM is making its mark in key application areas:

High-Performance Electric Vehicles:

AFM’s flat design allows for distributed or in-wheel motors, making it ideal for tight spaces and highly optimized layouts. Its high efficiency and compact form make it an ideal candidate for range extenders and performance-focused EV platforms.Wind Power:

AFM’s low-speed, high-torque characteristics enable direct-drive wind turbines, reducing tower load and installation costs.High-precision Equipment:

AFM shines in applications where space, weight, and instantaneous torque matter, such as drones, bionic robot joints, and precision machinery.

Summary

Axial flux and radial flux motors are not simply interchangeable alternatives — they are complementary technologies serving different needs. AFM, with its revolutionary flat design, sets new benchmarks for power density, efficiency, and weight optimization, pointing the way for future electric drive innovations.

While thermal management and manufacturing costs remain the final hurdles to AFM’s widespread adoption, its role in a future defined by efficiency, compactness, and raw performance — from electric cars to wind turbines — is already gaining momentum. The era of flat motor technology has arrived.

TEC precision servo motors focus on deep customization, offering high-performance solutions from 100W to 12kW. We specialize in high overload capacity, high speeds up to 20,000 rpm, ultra-low torque ripple of ±0.5%, and excellent temperature rise control, with support for wide temperature range customization from -40°C to 50°C. Designed in strict accordance with IEC/GB standards (insulation, cooling, vibration), we offer standard flanges from 40mm to 180mm as well as non-standard options. With a wide voltage platform of 12V–96V, our motors can be integrated with encoders, brakes, and support special OEM customization such as explosion-proof, low-temperature, and high-IP protection. They are widely used in servo applications with high demands for precision, reliability, and environmental adaptability, including industrial robot joints, high-end CNC equipment, semiconductor manufacturing, and AGV drive systems.