- By 小编

- 2025-05-13 16:14:18

- TECHNICAL

How to Choose the Right AGV Steering Wheel?

In the fields of automated logistics and industrial production, the steering wheel is a critical component that has a major impact on the performance of AGVs, mobile robots, and other equipment. Choosing the right steering wheel can make your equipment run more efficiently and stably—but with so many types and complex specifications, how do you select precisely? Today we’ll explain in detail.

I. Principle of Operation and Types of Steering Wheels

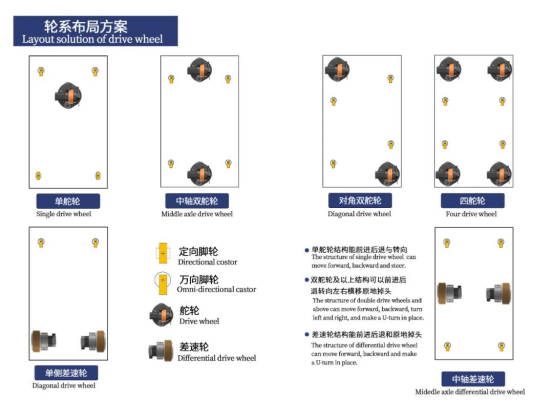

A steering wheel integrates a drive motor, a steering motor, a reducer, and more, combining driving and steering in one unit. By controlling the speed of the drive motor and the angle of the steering motor, the device can move forward, reverse, turn, and translate sideways—greatly improving maneuverability in complex environments. Depending on application and design, there are several main types:

Single steering wheel

Simple in structure and control, suitable for scenarios where the load position is fixed and the path is not too complex (e.g. basic material handling).Dual steering wheels (mid-axis or diagonal mounting)

Higher rated load, can drive heavier AGVs, and enables sideways shifts and on-the-spot rotation—commonly used in heavy-load logistics requiring high flexibility.Four or more steering wheels

More complex motion control but extremely high flexibility and stability, ideal for environments demanding maximum space utilization and precision.

II. Preparation Before Selection

Clarify the application environment

Is it in a warehouse, factory floor, or outdoor site? Different environments impose different performance and protection-rating requirements. For example, indoor warehouses may need lower IP ratings, whereas outdoor sites demand resistance to dust, rain, and harsher conditions.Determine load requirements

Calculate the vehicle’s own weight plus the maximum cargo weight to find the total load each wheel must bear. Also consider any acceleration or incline requirements—if present, choose wheels with higher traction and load capacities.Plan operating speed

Based on your workflow, establish the required speed range and ensure the chosen steering wheel can meet and exceed that speed, with an appropriate safety margin.

III. Key Parameters Explained

(1).jpg)

Speed

Steering-wheel speeds typically range from 60–70 m/min. Choose a wheel whose maximum exceeds your design speed to accommodate acceleration and load changes.Traction (Drag) Load

Determines the wheel’s ability to pull the vehicle and cargo. Normally specified as the ability to accelerate to rated speed within 5–10 s on flat, level ground. If you need hill-climbing or rapid acceleration, select a larger model; for slower speeds and lighter acceleration, a wheel whose drag load is slightly below the vehicle weight may suffice.Static Load Capacity

The maximum weight the wheel can support without damage. AGVs typically distribute weight between steering wheels and support (idler) wheels, so use the steering-wheel load capacity as a reference when designing weight distribution.

Motor Type

Brushed DC (permanent-magnet) motor: High starting torque, strong overload capacity, easy control, widely used in industrial vehicles. Brushes wear over time and are unsuitable for cleanroom or explosive-hazard environments. Common in automotive assembly-line AGVs.

AC induction motor: High torque and overload tolerance, robust and maintenance-free, but harder to control precisely; used in parked AGVs and laser-guided forklifts.

Brushless DC / PMSM (permanent-magnet synchronous) motor: Easy control, high precision, maintenance-free, but lower overload capacity; ideal for light-load, low-inertia, high-speed applications (e.g. LCD panel carts, cleanroom sorters).

IV. Other Considerations

Mechanical Dimensions

Wheel height: Determines the minimum chassis height of the AGV—choose to fit overall vehicle-height constraints.

Turning radius: Dictates the minimum space needed for installation—confirm sufficient clearance.

Wheel diameter: Affects top speed in conjunction with motor RPM and gearbox ratio.

Brand and Service

Select well-known brands for more reliable quality and stability. A robust after-sales service network is crucial to resolve issues quickly, minimizing maintenance costs and downtime.Cost Factors

Balance purchase price, operating cost (energy, maintenance), and performance. Aim for the highest cost-performance ratio while meeting technical requirements.

Steering-wheel selection involves many factors but follows a clear methodology. We hope this guide helps you cut through the complexity and choose the right wheel for efficient, reliable operation. If you have any questions during your selection process, feel free to leave a comment!