- By YIKONG

- 2025-03-10 13:40:56

- TECHNICAL

Frameless torque motor: technological innovation and manufacturing challenges of joint drive of humanoid robots

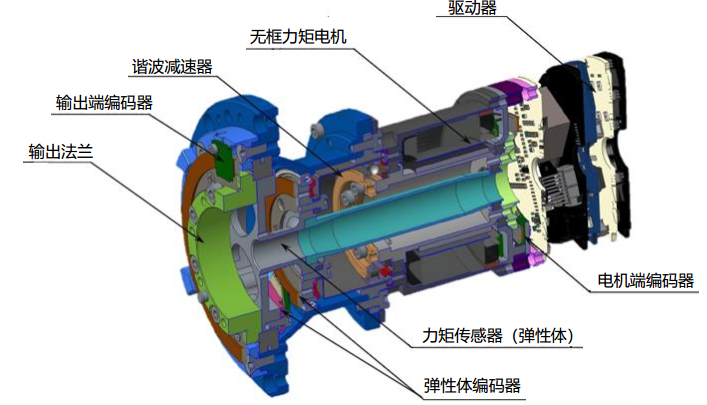

1. Technical principles and structural innovation

Frameless Torque Motor abandons the shell, bearing and other components of traditional motors, and only retains the core rotor (permanent magnet assembly) and stator (copper winding and steel sheet) to achieve power output by directly embedding the mechanical structure. Its design features include:

High power density: The frameless structure reduces redundant components, reduces volume by 30%-50%, and improves torque density by 15%-20%.

Low inertia response: The rotor has low inertia and short response time, which can support the instantaneous explosive force requirements of the robot joints (such as bounce, fast running).

Customized compatibility: supports modular design and adapts to different joint sizes (such as Tesla Optimus uses 28 frameless motors to drive joints).

Technical difficulties focus on magnetic circuit optimization and heat dissipation design. For example, the German TQ Robodrive adopts a 20-pole 18-slot magnetic circuit layout to improve heat dissipation efficiency through epoxy potting; the United States Kollmorgen uses a 12-pole 39-slot design to reduce torque pulsation to ensure stable operation.

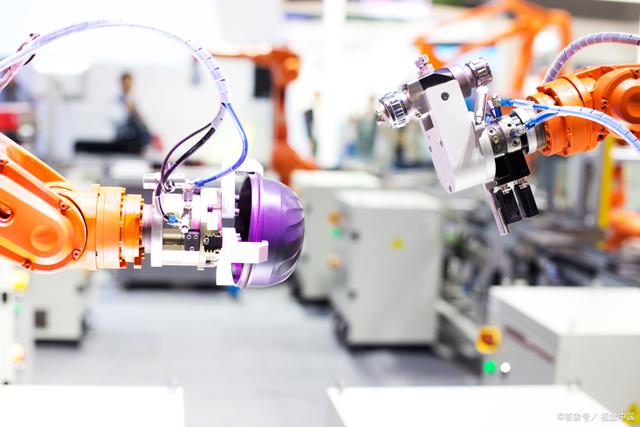

2. Application scenarios: Comprehensive penetration from industry to bionics

The core application scenarios of frameless torque motors have been expanded from traditional industrial robots to high-precision fields such as humanoid robots and medical equipment:

Humanoid robot joints:

Among the 28 joints of Tesla Optimus, the frameless motor undertakes rotation and linear drive, and the single-machine value accounts for about 15.4%.

The joint module of Wolong Electric Drive combines AI technology to simulate the movement characteristics of human bodies and adapt to inspection and rescue tasks in complex environments.

Collaborative Robots: Each collaborative Robot requires 6-7 frameless motors, and its compact design (minimum diameter 25mm) supports high flexibility operation.

Medical and precision manufacturing:

In surgical robots, the motor accuracy can reach micron level and support minimally invasive operation;

In the field of machine tools, direct drive technology eliminates mechanical transmission errors and improves processing repeatability.

3. Manufacturing technology: precision processing and domestic breakthroughs

The manufacturing of frameless torque motors involves high-precision machining and electromagnetic design, and the core links include:

Materials and Equipment:

Wire winding and potting technology:

The third-generation product of Buke Co., Ltd. adopts split-flap winding design and frameless potting technology to improve heat dissipation efficiency and structural stability;

Leisai Intelligent's FM1 series optimizes the winding groove full rate and has a torque density of 15% higher than that of its peers.

Progress in domestic production:

Buke shares account for nearly 50% of the domestic market share, with the product outer diameter covering 52mm-132mm, which is suitable for multi-scenario demand;

Leisai Intelligent launches 25mm micro motors, which will enter the trial production stage in 2024, and its target customers include multiple humanoid robot companies.

4. Competitive landscape: Domestic substitution opportunities led by foreign capital

Foreign brands: Kollmorgen (US), TQ Robodrive (Germany), etc. occupy the high-end market, and their technical advantages lie in magnetic circuit simulation and process stability.

Domestic manufacturers:

Buke Co., Ltd.: The performance of the third-generation product is benchmarked against international standards, and the fourth-generation R&D focuses on lightweighting and cost optimization.

Leisai Intelligent: The micro drive and humanoid joint module have entered trial sales, and the production capacity plan for 2024 is clear.

Wolong Electric Drive: Joint AI technology to develop bionic joint systems to expand vertical scenarios such as power and medical care.

Market prospects: The global frameless motor market size for humanoid robots is expected to reach 6 billion yuan in 2025, and may exceed 28 billion yuan in 2030. The domestic substitution rate is expected to increase from 30% to 50%.

5. Challenges and future trends

Technical bottlenecks:

The torque density and reliability of high-end products are still lagging behind foreign brands;

Temperature rise control and customization requirements increase process complexity.

Innovation direction:

Double stator design: For example, a patented solution improves impact resistance through internal and external stator layout, adapts to the high load requirements of industrial robots

Intelligent integration: integrated design of driver, encoder and motor to reduce signal interference (such as Haozhi Electrical Joint Module)

Industrial chain collaboration: Upstream magnetic material companies and downstream robot manufacturers jointly develop customized solutions to accelerate the implementation of scenarios

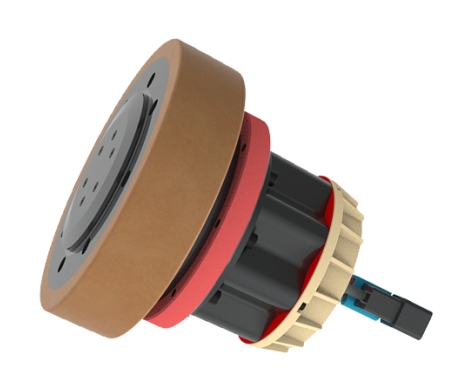

Sixth, Servo Integrated Wheel: Performance Transfer of Frameless Torque Motor

Our servo wheels are integrated as an integrated carrier of frameless torque motors, deeply integrate motors, drivers, encoders and wheel bodies to create a compact unit with the "power-control-execution" trinity. Its core advantage lies in its ultimate space utilization and explosive dynamic response - taking the typical design with an outer diameter of 80mm as an example, it can output 150N·m peak torque and carry 100kg dynamic load, but it can save traditional reducer and transmission structure, increasing the layout freedom of AGV chassis or humanoid robot joints by more than 40%.

The low inertia characteristics of the frameless torque motor compress the wheel response time to the 2ms level. Whether it is precise parking of ±0.1mm within the narrow path of the storage robot 0.5 meters, or the instantaneous reverse driving of the ankle joint of the humanoid robot when it touches the ground, it can achieve millisecond-level force-control interaction. Direct drive technology further eliminates mechanical transmission losses, reduces energy consumption by 15%-20% under the same load, and combines the integrated packaging of IP65 protection grade, even in industrial scenarios with dust, oil pollution or high-frequency vibration, it can still ensure fault-free operation for more than 20,000 hours.

More importantly, this type of design supports multiple rounds of coordinated and force-level hybrid control through built-in bus protocols (such as EtherCAT). For example, when climbing a hill and crossing obstacles, the system can distribute the torque of each wheel in real time to simulate the coordinated force of biological muscle groups; in high-sensitivity scenarios such as surgical robots, its micron-level positioning accuracy and flexible output characteristics can even restore the operating touch of human fingers. This feature of "hardware is the algorithm carrier" is redefining the boundaries of robot motion control.

Conclusion

As the "muscle system" of humanoid robots, the frameless torque motors are directly related to the robot performance ceiling. Although domestic enterprises still have a gap between process accumulation and high-end market, they are gradually breaking the monopoly of foreign investment through differentiated innovation (such as miniaturization, high cost performance) and the coordinated industrial chain. In the future, with the wave of mass production of humanoid robots driven by AI, this track may usher in an "explosive growth cycle".