Product Introduction

Our grid production process is the mesh drawing method. Compared with traditional high-temperature casting, it has higher strength and better corrosion resistance. It also reduces the weight of the battery and reduces pollution during the production process.

Other manufacturers generally use a single-pass sealing process. If the workers are negligent, it will cause acid leakage at the terminal. We use a double-pass sealing process: the first pass is lead sealing welding, and the second pass is acid-resistant sealing to ensure that even if the workers are negligent, there will be no acid leakage.

The internal resistance of our lead-acid battery is 5-5.5mΩ. The national standard requires that the deviation of the same group of batteries is ≤3.39%, and our battery deviation is <2.99%. In addition, the national standard also requires that the capacity retention rate after 28 days of standing is >98%. Our battery capacity reaches 99.2%, which greatly exceeds this standard.

Product application cases

Starter Battery (SLI)

The largest use for lead-acid batteries remains as automotive starting batteries. This application, called starting, lighting, and ignition (SLI), matches well with the lead-acid battery’s ability to produce the high currents required to start a cold internal combustion engine (ICE).

Forklift

Battery-powered forklifts have largely replaced gas-powered forklifts. In addition to lower operating costs, electric forklifts can be operated inside buildings or enclosed spaces without worrying about toxic exhaust fumes and deadly carbon monoxide buildup.

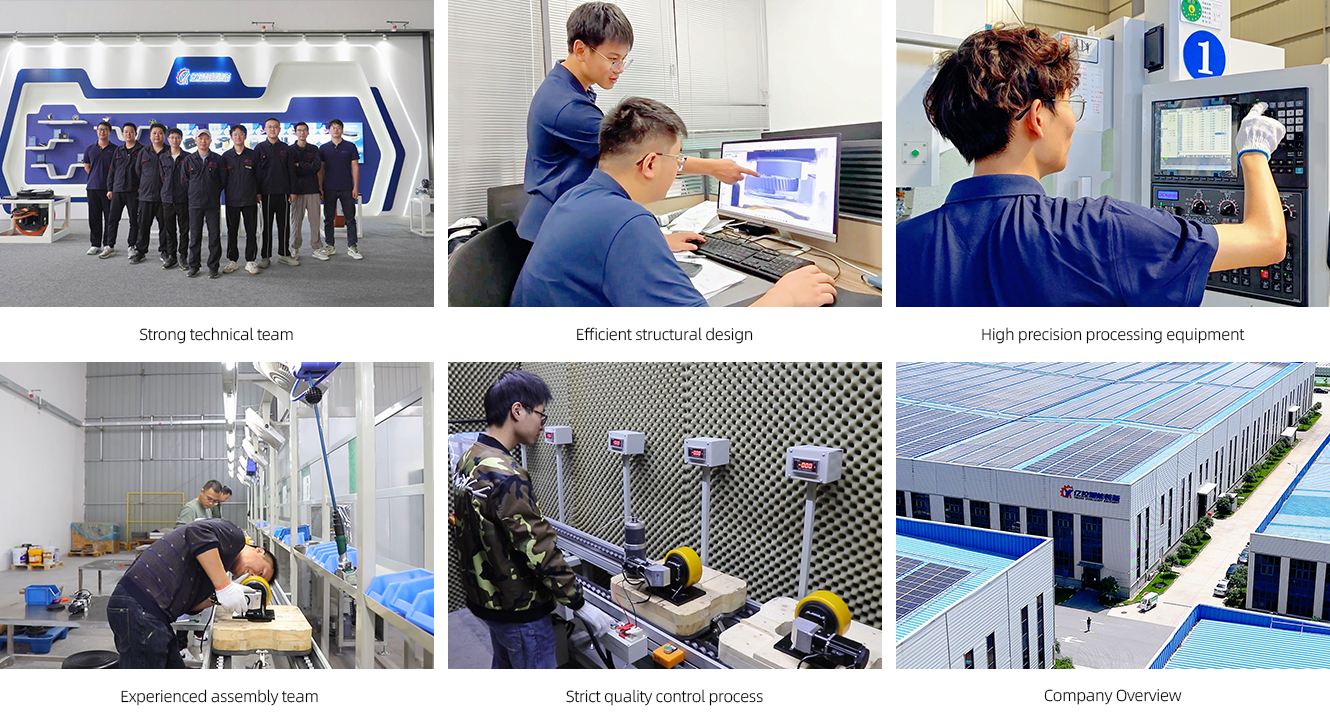

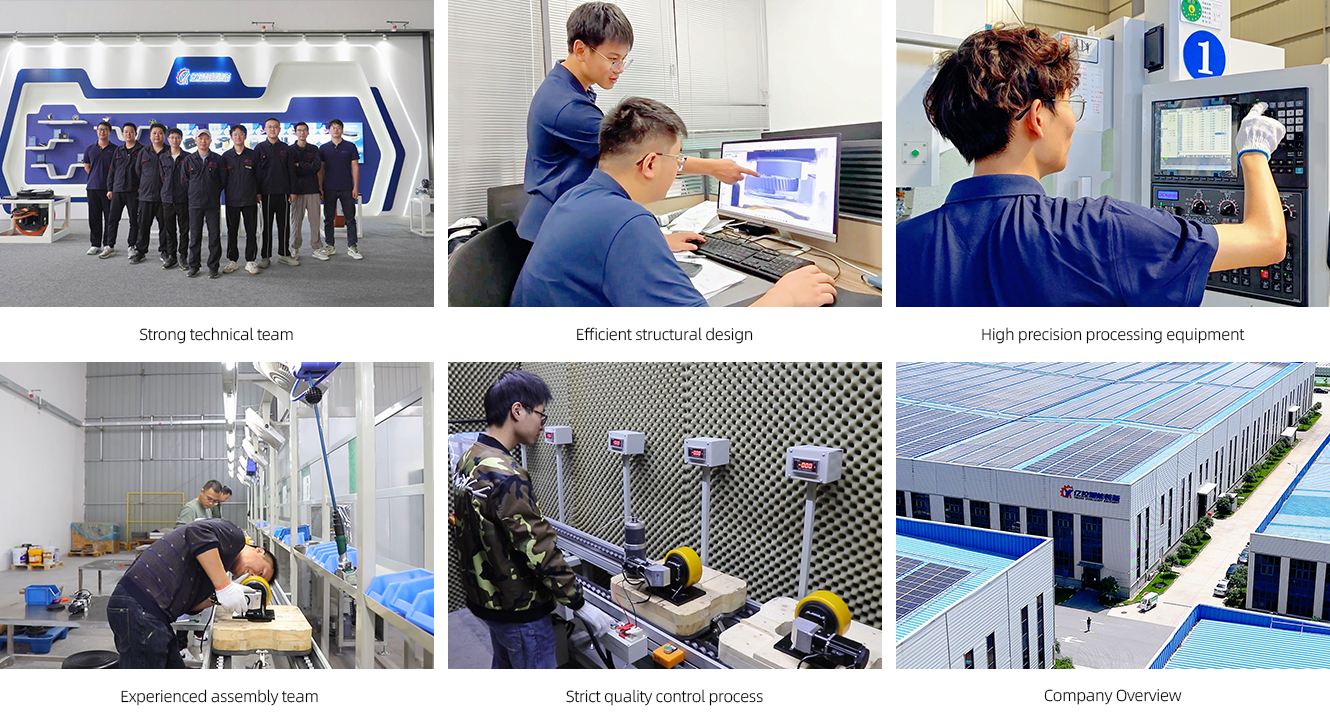

Six quality assurances

FAQ

They are used for backup power supply of alarms and small computer systems (especially uninterruptible power supplies) as well as backup power supply of electric scooters, electric wheelchairs, electric bicycles, marine applications, AGVs, forklifts, battery electric vehicles or micro hybrid cars and motorcycles.

Lead-acid batteries have been used for over 160 years in many different applications and remain the most widely used rechargeable electrochemical device for small to medium storage applications. They are safe, low cost, simple to charge, and easily recyclable.

A lead-acid battery is a rechargeable battery that uses lead and sulfuric acid to work. The lead is immersed in sulfuric acid to create a controlled chemical reaction. This chemical reaction allows the battery to produce electricity. The reaction is then reversed to recharge the battery.