Product Introduction

Rubber drive wheels are usually made of high-quality rubber materials with good wear resistance, impact resistance and anti-slip properties. Such drive wheels can provide stable power transmission under various ground conditions to ensure the normal operation of the equipment.

Its design takes into account different application scenarios and is suitable for various industrial equipment, logistics handling equipment, etc. The rubber material can reduce noise and vibration, bringing a more comfortable experience to the operating environment.

In addition, the rubber drive wheel has good elasticity, can adapt to a certain degree of terrain changes, and can be used in conjunction with other components to provide reliable connection and transmission.

Application Scenario

Factory automation production line:

In various automated production lines, rubber drive wheels can be used to drive conveyor belts, roller conveyors and other conveying equipment. They can operate stably under different ground conditions in the factory to ensure the smooth transportation of products. For example, in automobile manufacturing plants, rubber drive wheels can drive automobile parts to move accurately to various assembly stations on the production line.

Industrial robots:

Some moving parts of industrial robots may use rubber drive wheels to achieve flexible movement and precise positioning. The good elasticity and anti-slip performance of rubber drive wheels can ensure the stable operation of robots in different working environments and improve production efficiency and quality.

Forklift:

Forklift is a commonly used equipment in logistics warehousing. The driving wheels of forklift are generally made of rubber. The rubber driving wheels can provide good grip and stability, allowing the forklift to transport goods safely and efficiently on different floors such as cement floors and epoxy floors in the warehouse.

Automated Guided Vehicle (AGV):

AGV is responsible for the automated transportation of goods in logistics warehouses. The rubber drive wheels can provide it with smooth driving performance and precise navigation control. The shock-absorbing effect of the rubber material can also protect the goods on the vehicle from damage.

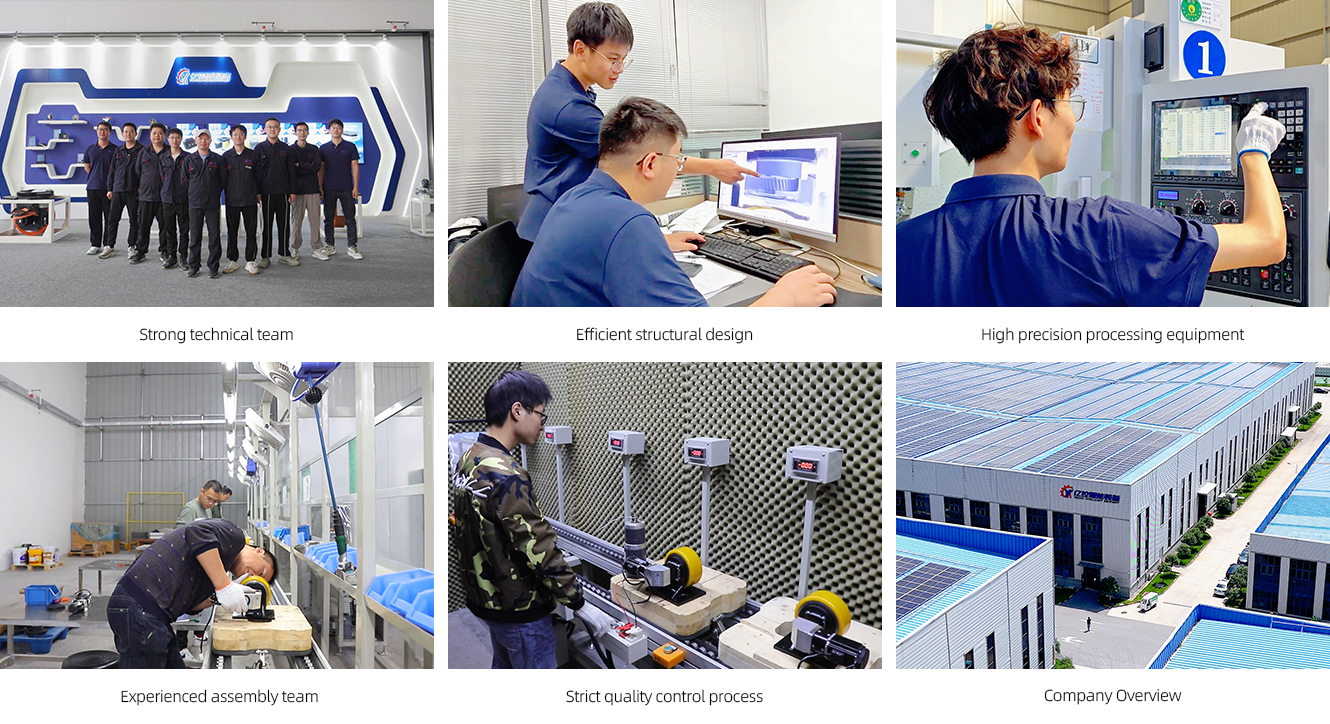

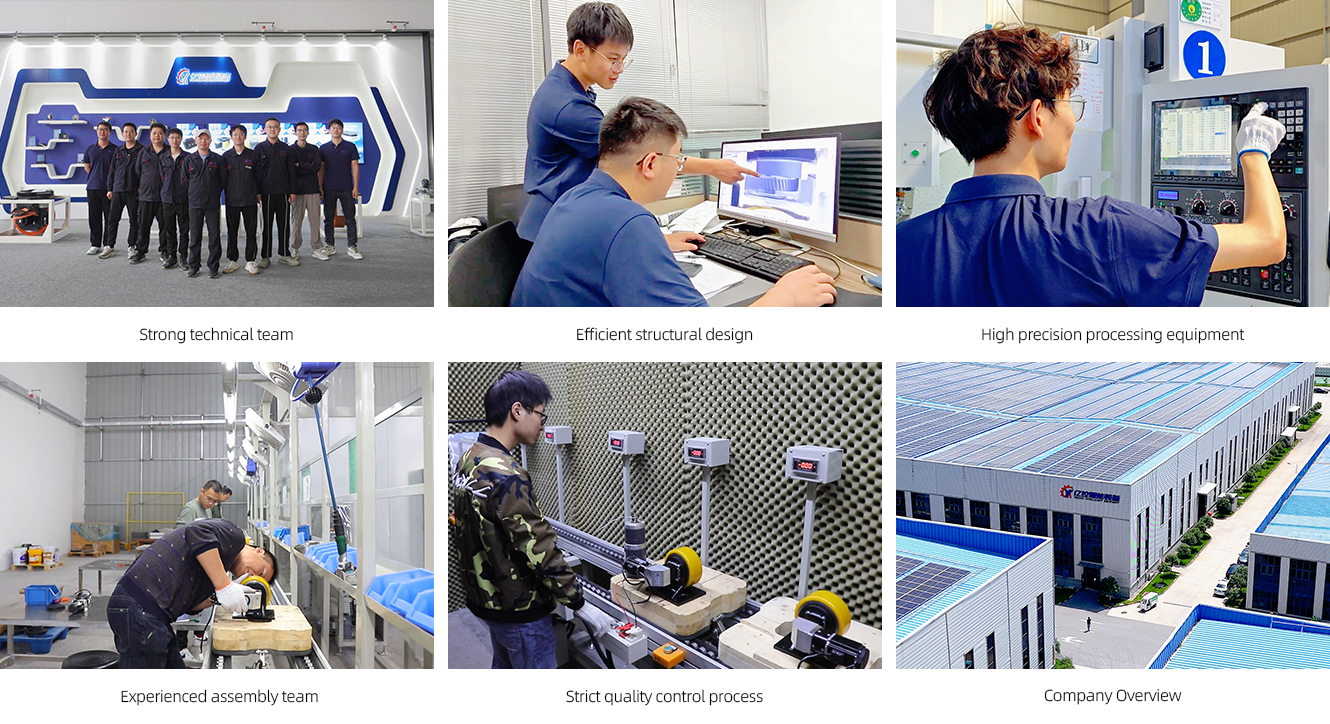

Six quality assurances

FAQ

Clean the rubber drive wheel regularly to remove dirt and debris from the surface. Check for wear. If severe wear is found, replace it in time. Rubber drive wheels with bearings or other parts that need lubrication should be lubricated and maintained regularly. When storing, place them in a dry and ventilated place, away from direct sunlight and high temperature environment.

Rubber drive wheels are suitable for a variety of floors, including relatively flat floors such as cement floors, epoxy floors, and tile floors. They can also be used for a short time on slightly uneven floors such as dirt roads and gravel roads, but long-term driving on floors with too many sharp objects should be avoided.

The rubber drive wheel has good wear resistance, impact resistance and anti-slip properties. It can provide stable power transmission under various ground conditions, reduce noise and vibration, and bring a more comfortable experience to the working environment. At the same time, it has good elasticity and can adapt to a certain degree of terrain changes.